From furnaces, heaters, and buildings to solar panels, flares, tanks, our comprehensive services cover a wide range of areas. At Maverick Inspection, we are dedicated to helping you identify potential issues, optimize performance, and ensure the utmost safety and efficiency of your assets through our top-notch thermal inspection solutions.

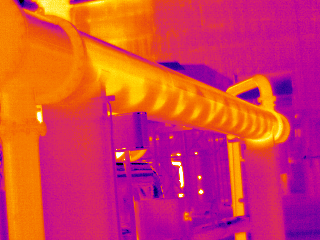

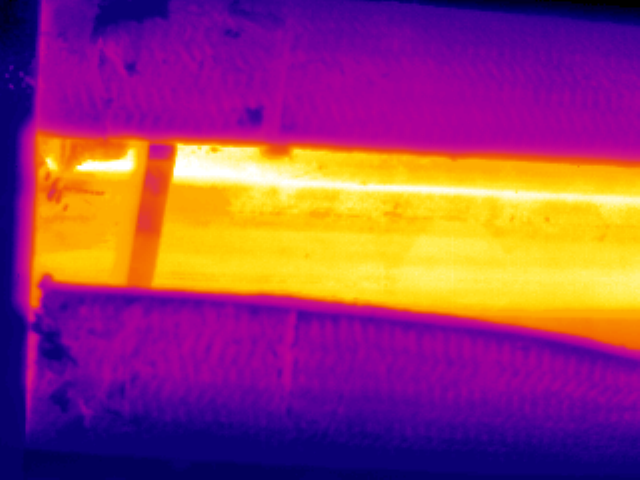

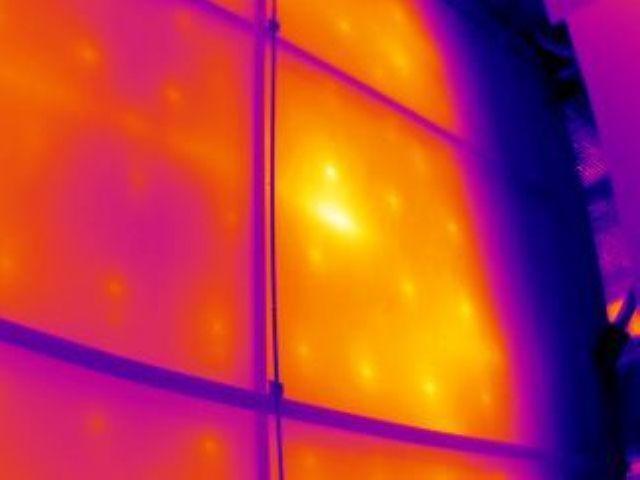

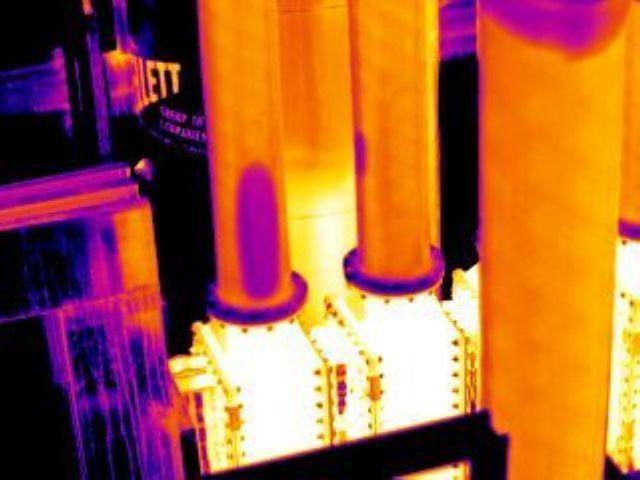

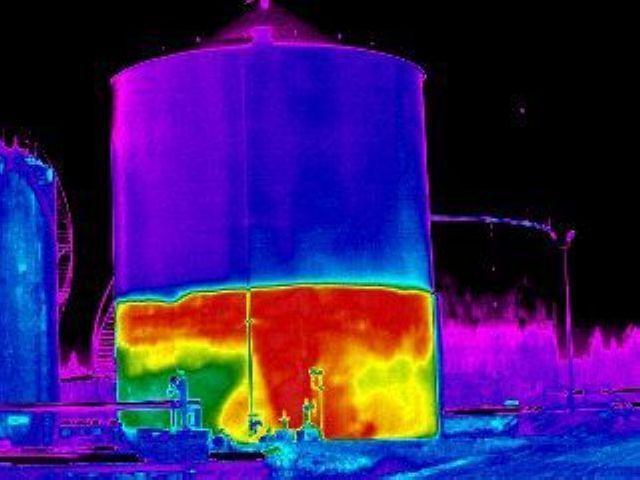

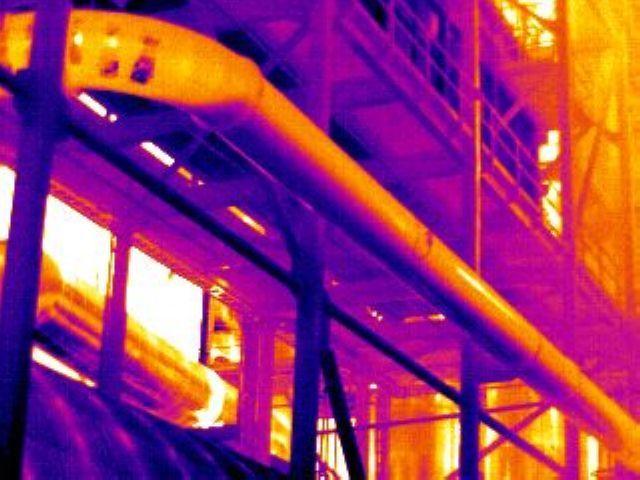

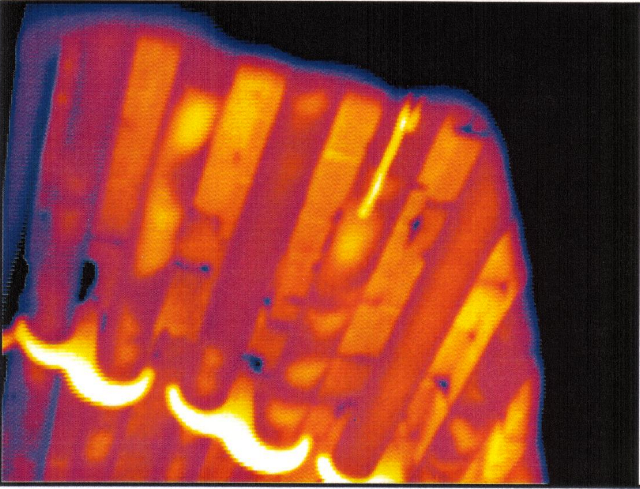

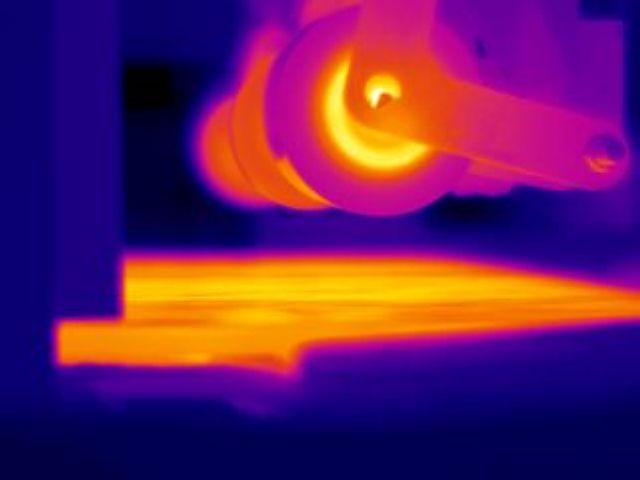

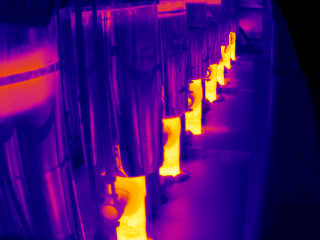

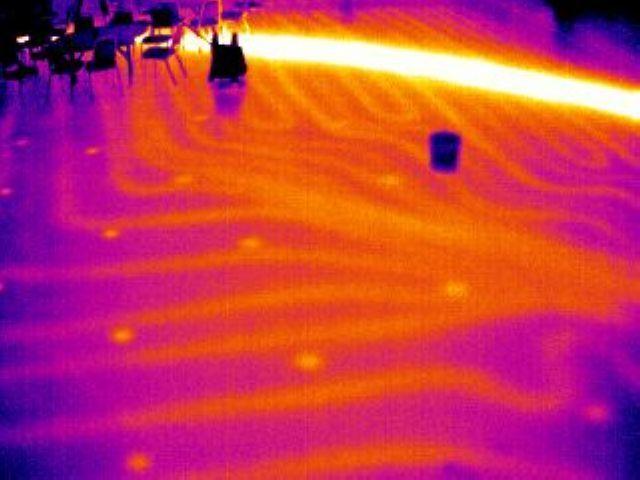

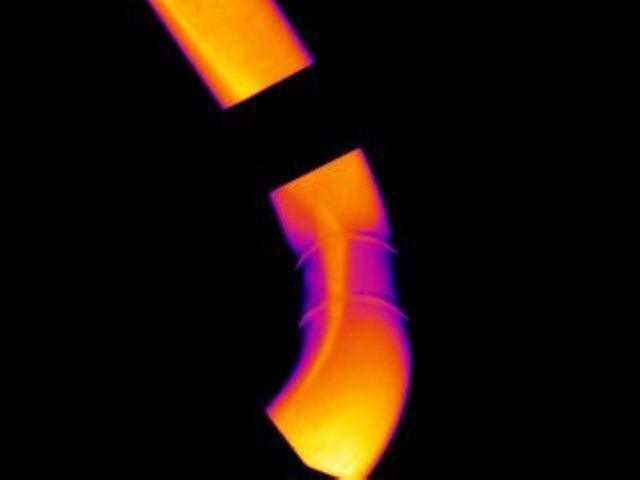

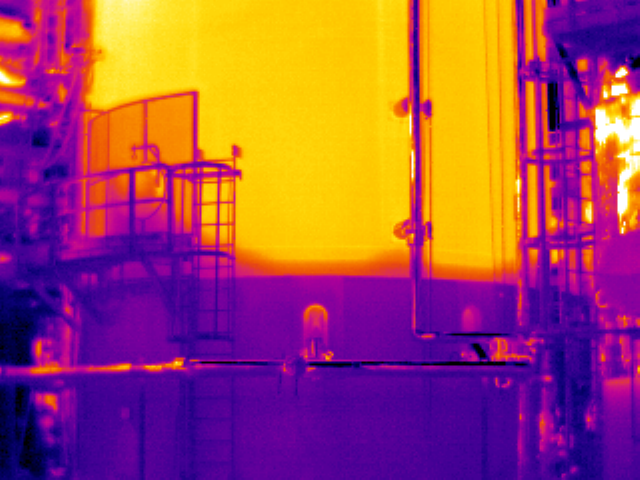

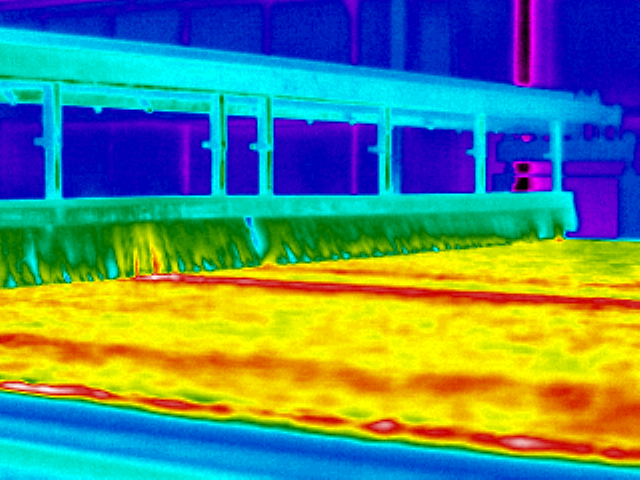

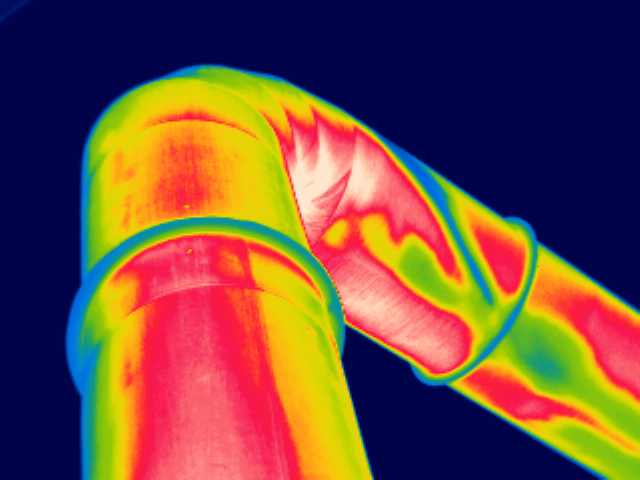

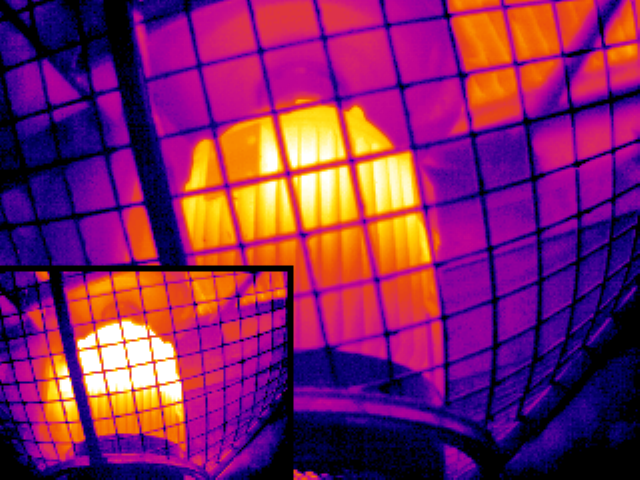

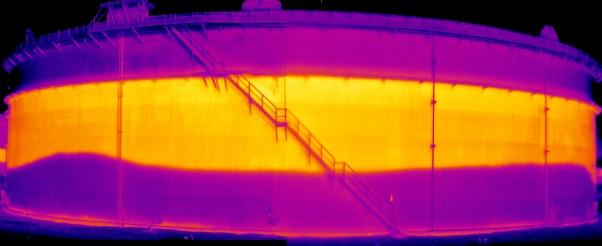

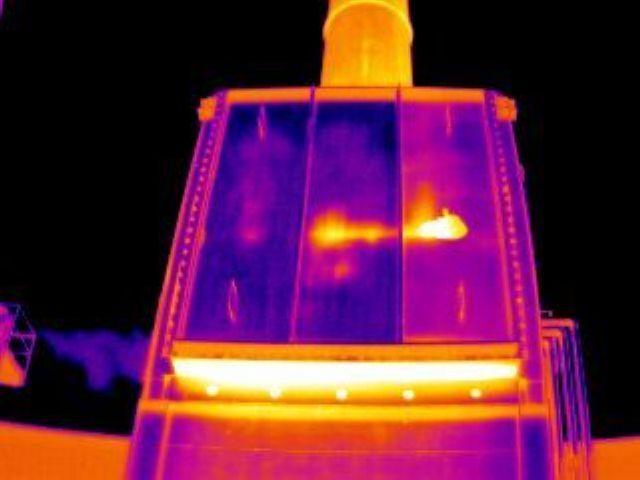

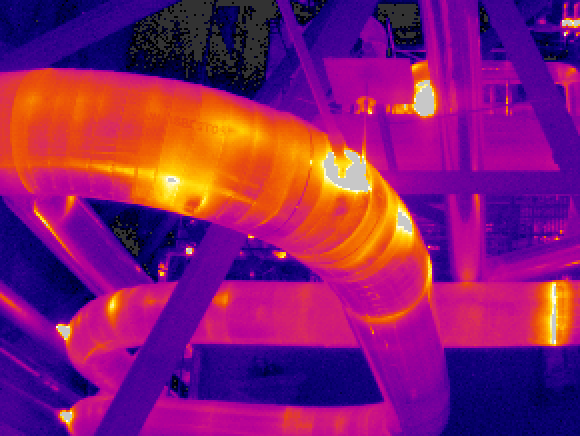

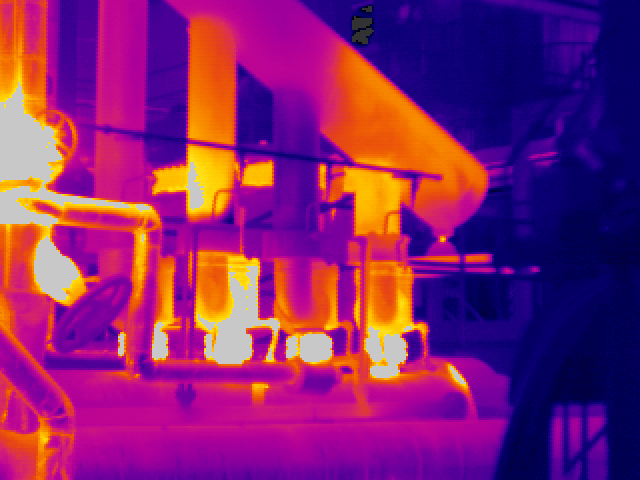

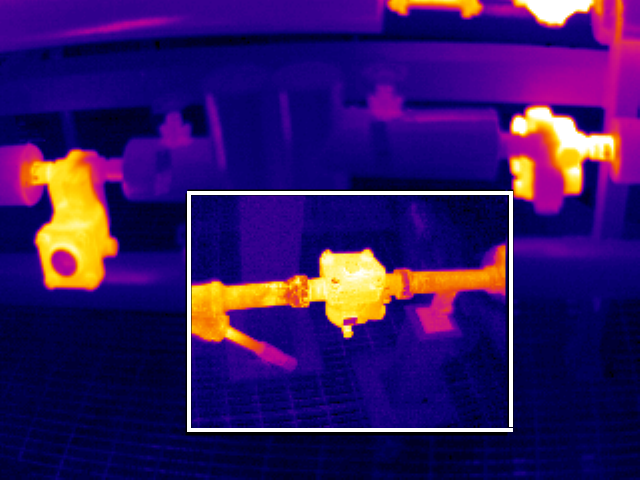

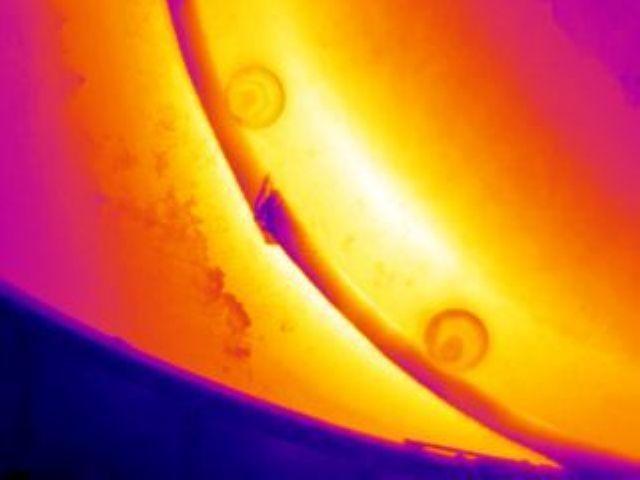

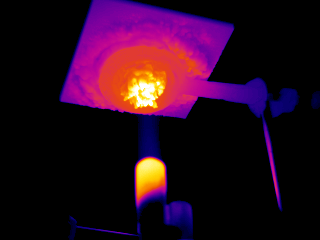

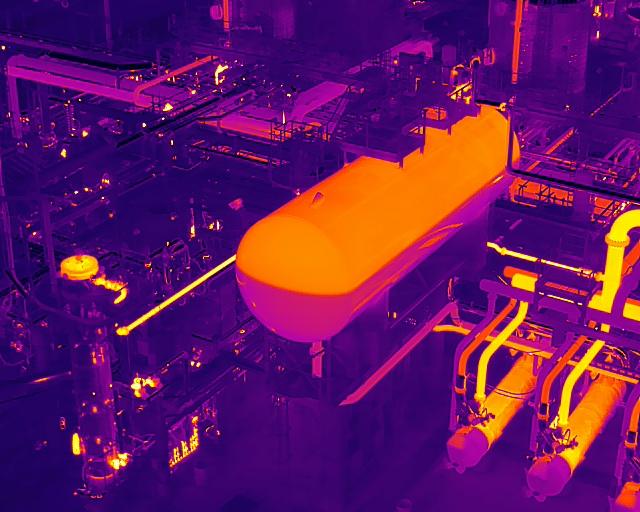

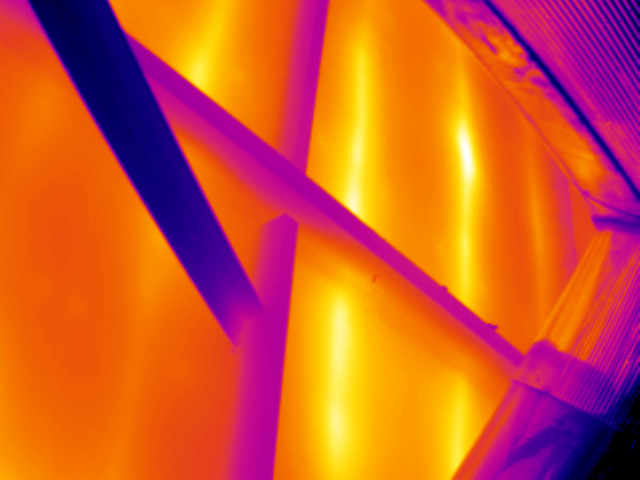

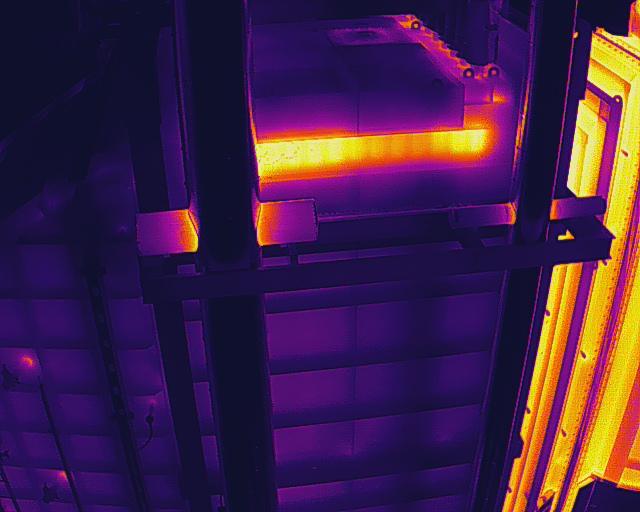

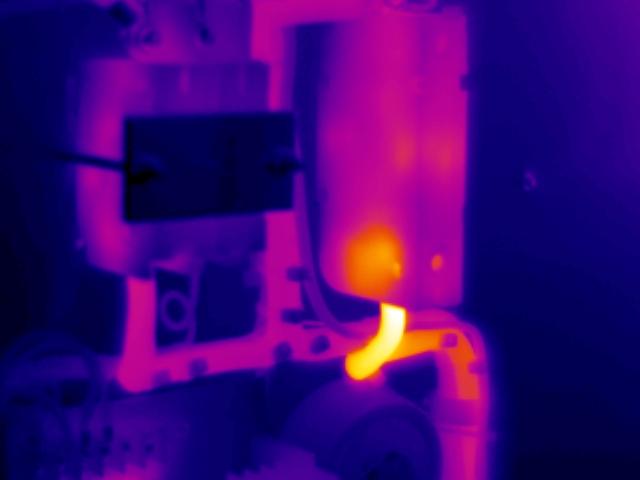

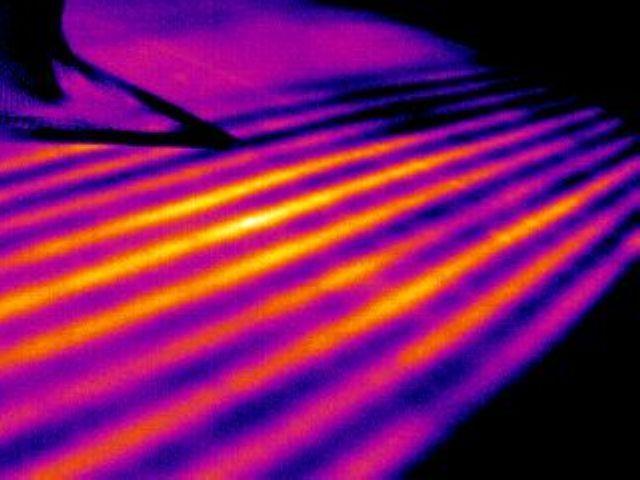

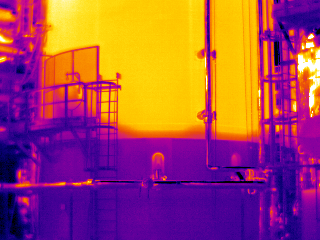

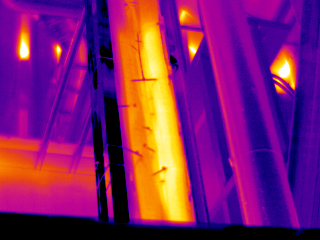

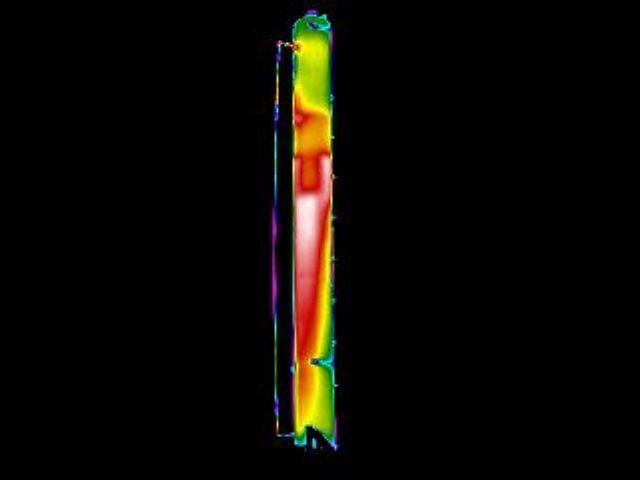

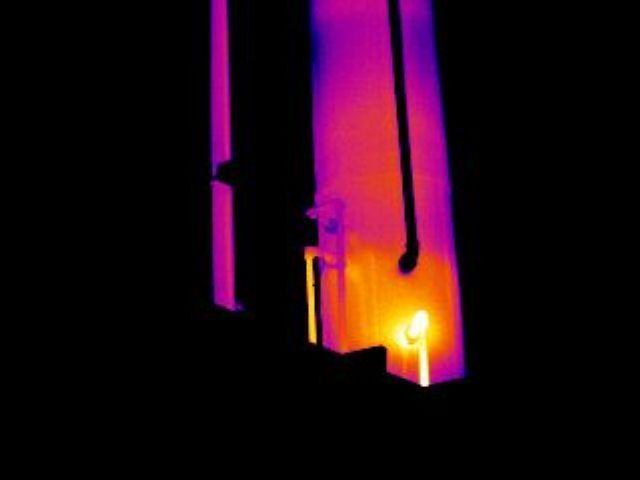

Industrial Thermography Photos

Gain an deeper insight into industrial processes with a thermal camera.

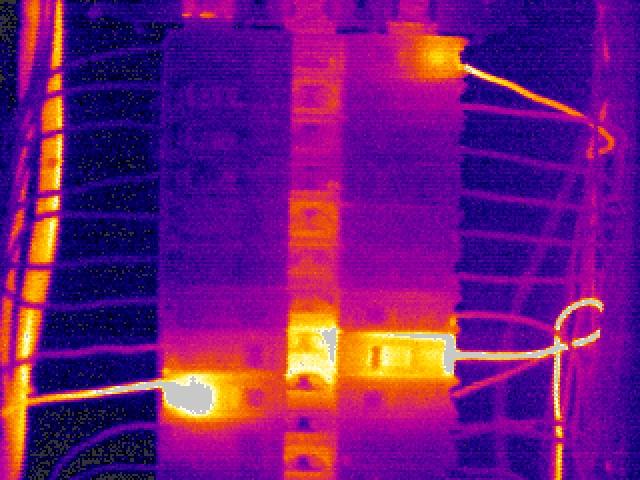

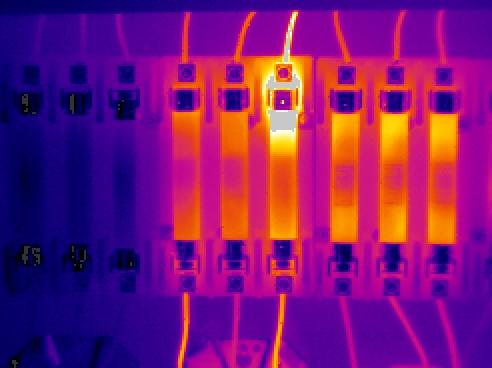

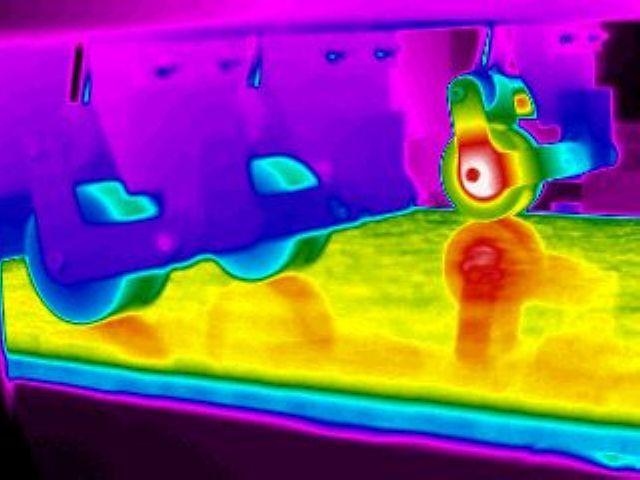

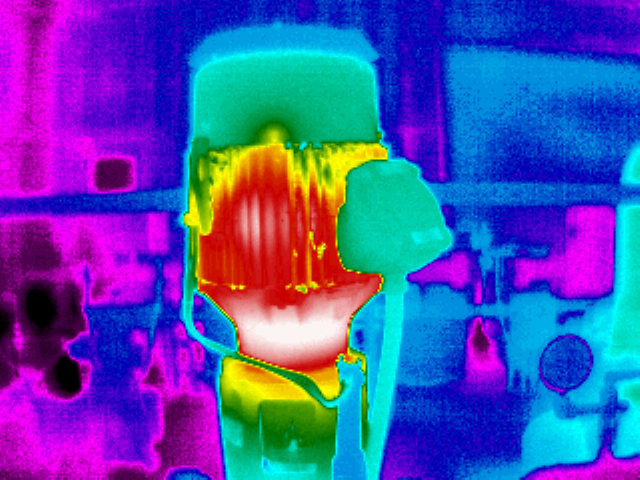

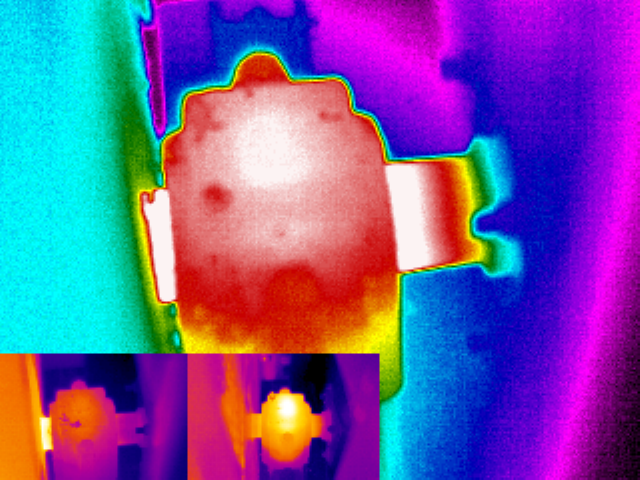

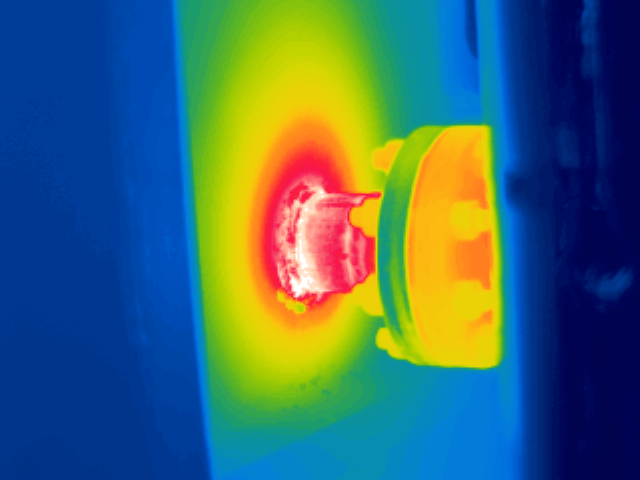

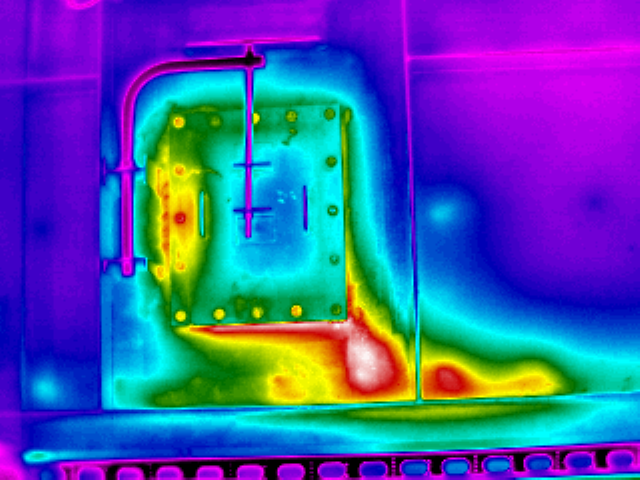

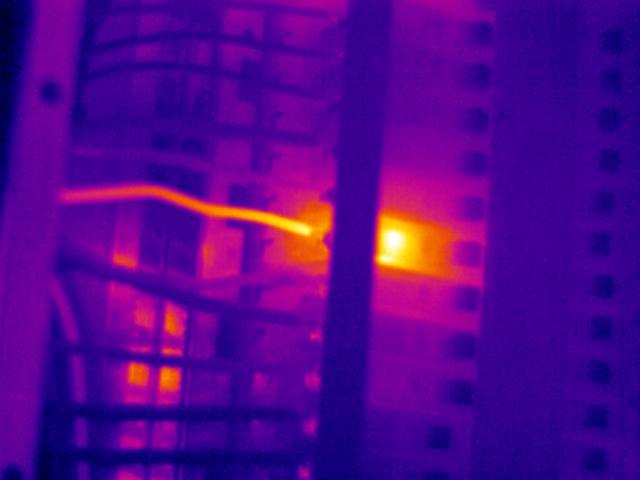

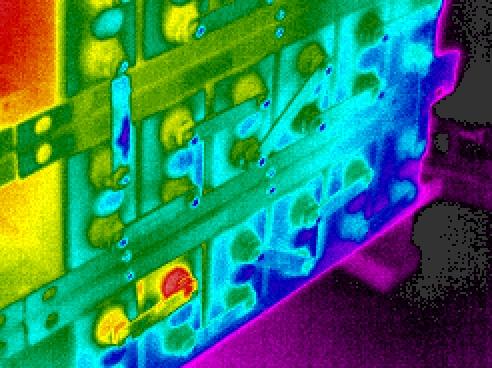

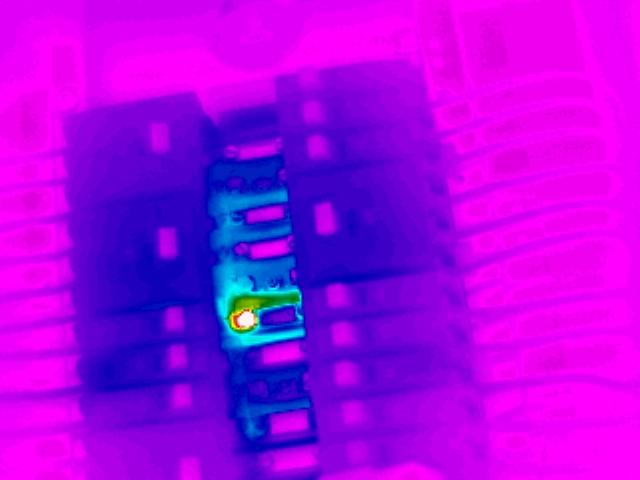

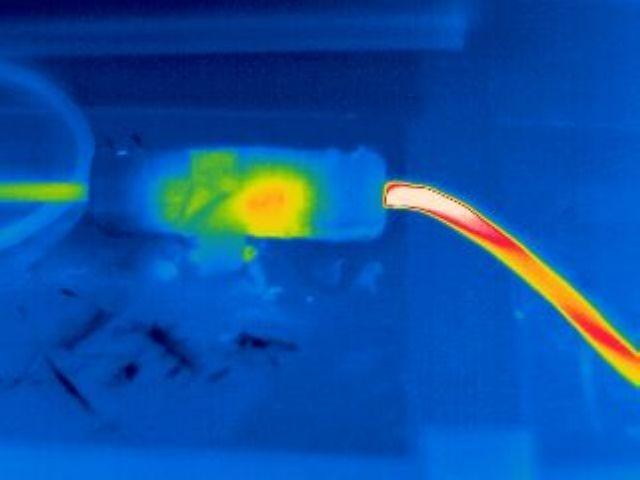

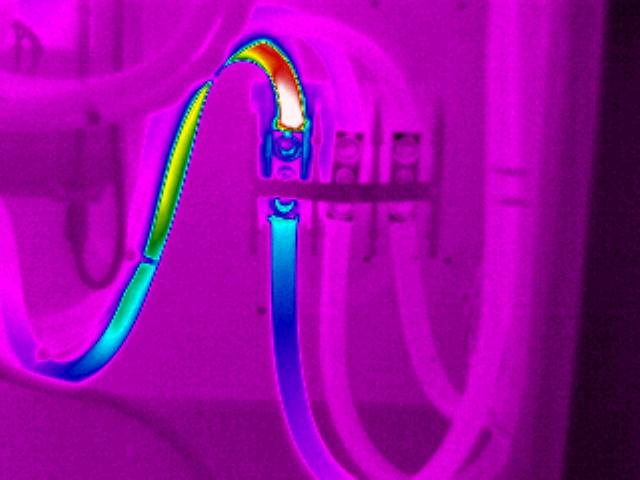

Electrical Thermography Photos

Use thermography as an important tool for electrical system commissioning and maintenance.

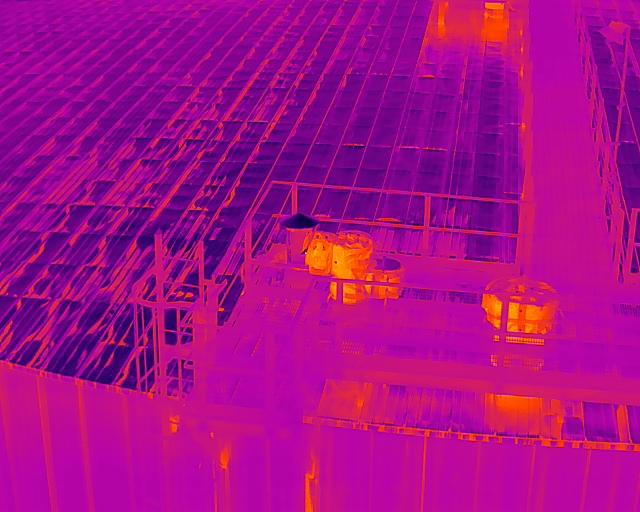

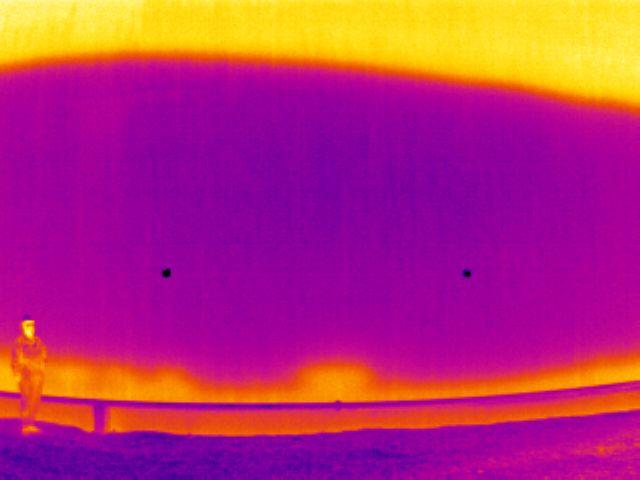

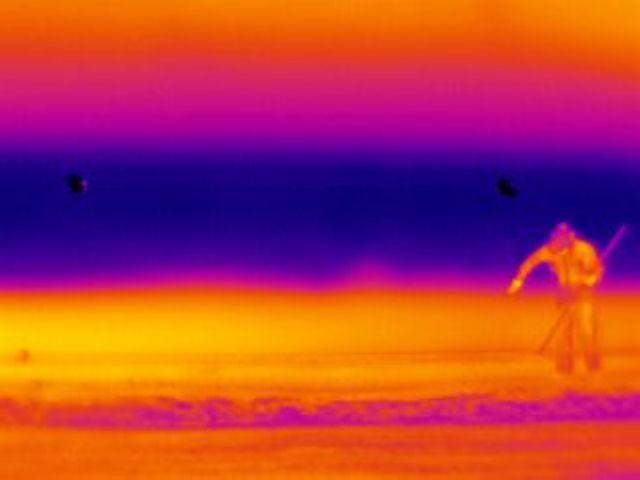

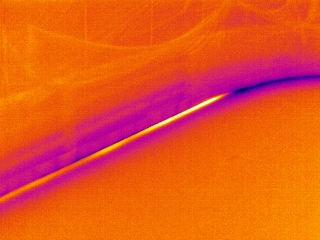

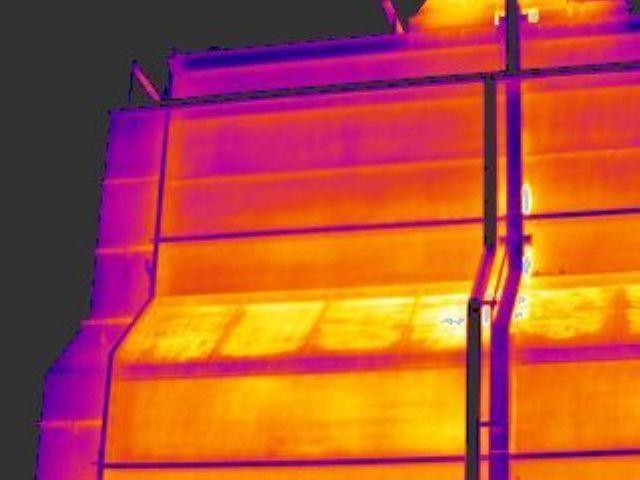

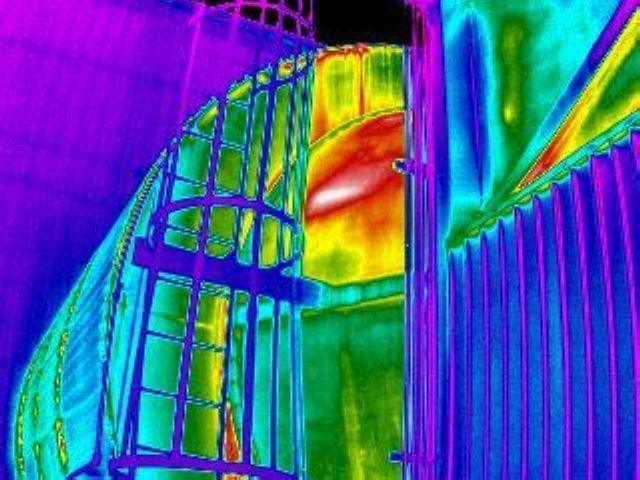

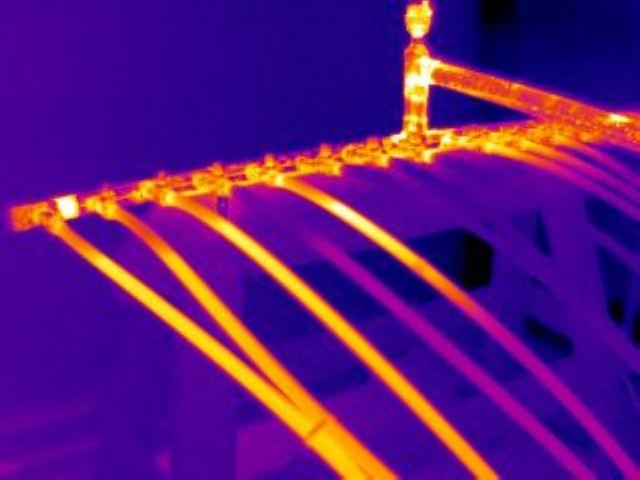

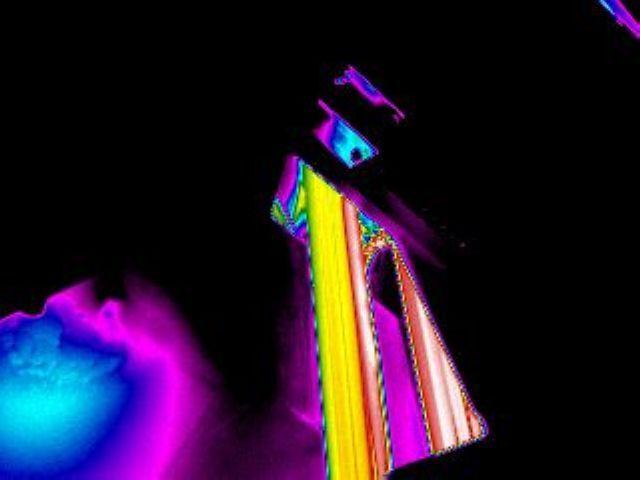

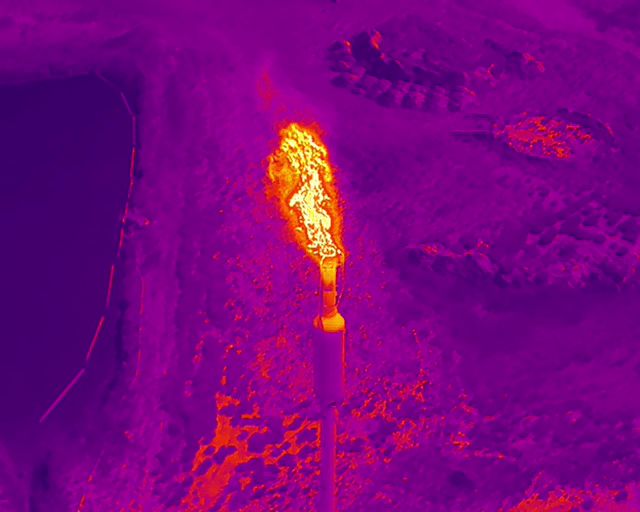

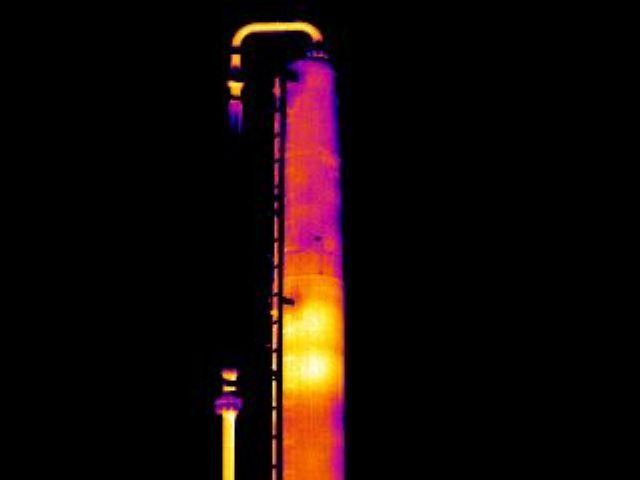

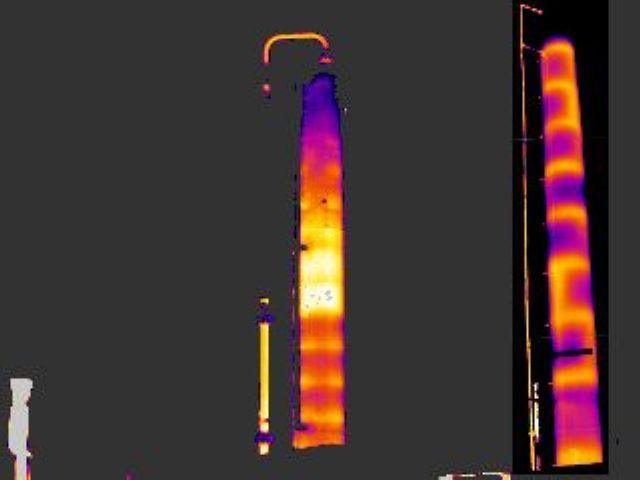

Drone Thermal Inspection Photos

Asset Inspections including Flares, Towers, Galleries and Facade Inspections.

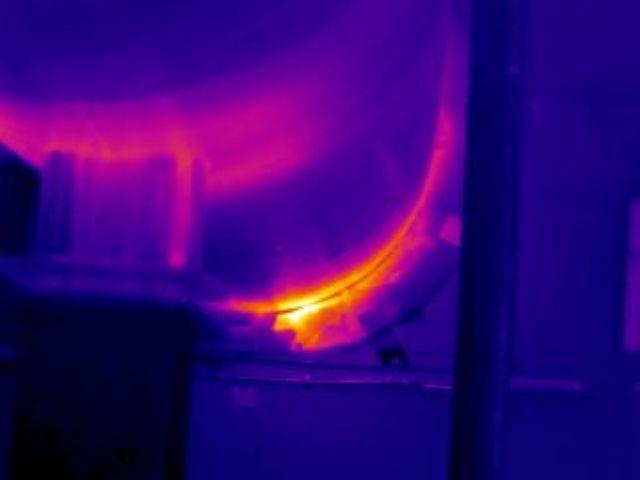

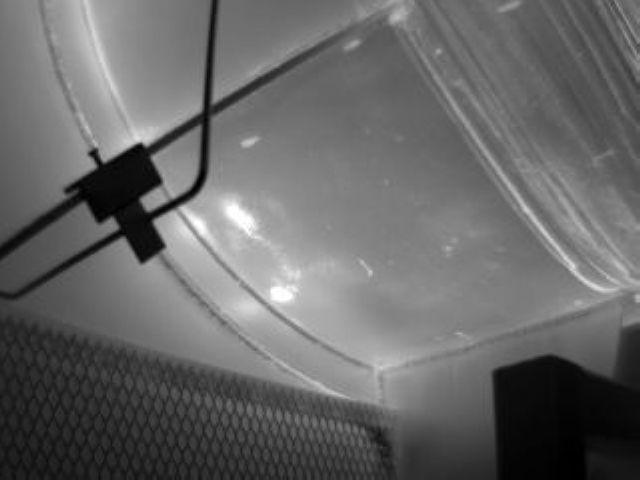

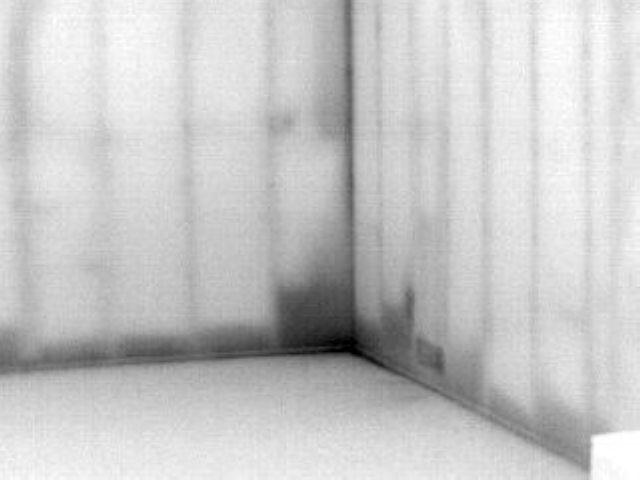

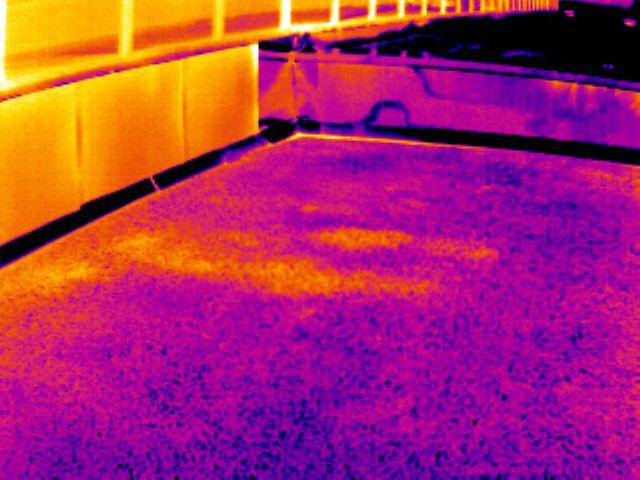

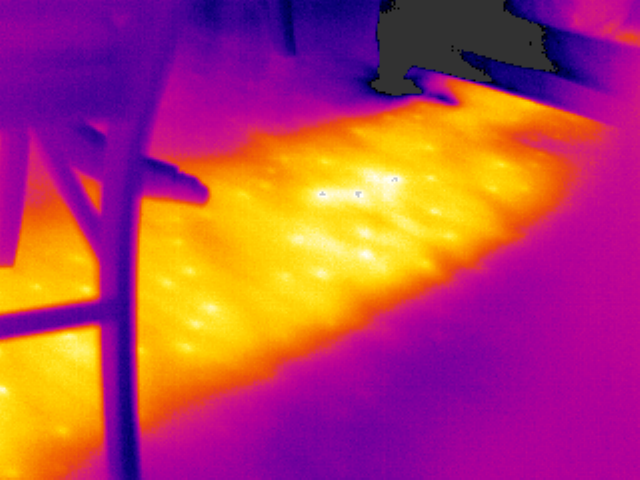

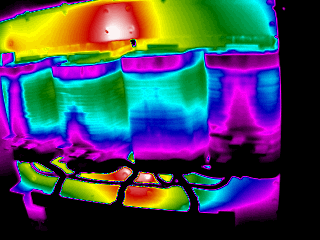

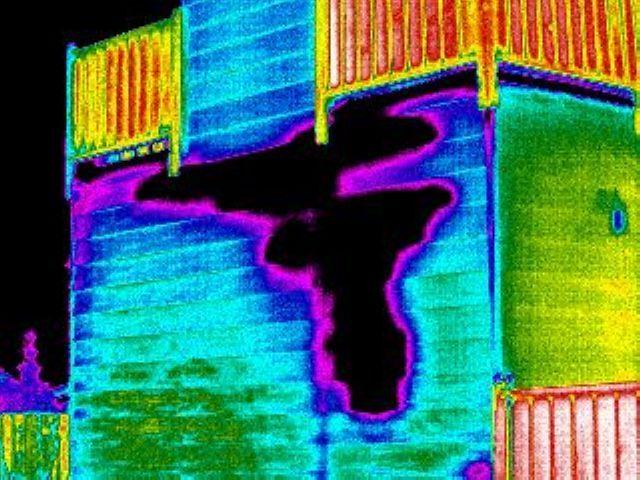

Building Maintenance Thermography Photos

Complete building envelope inspections with a FLIR camera.

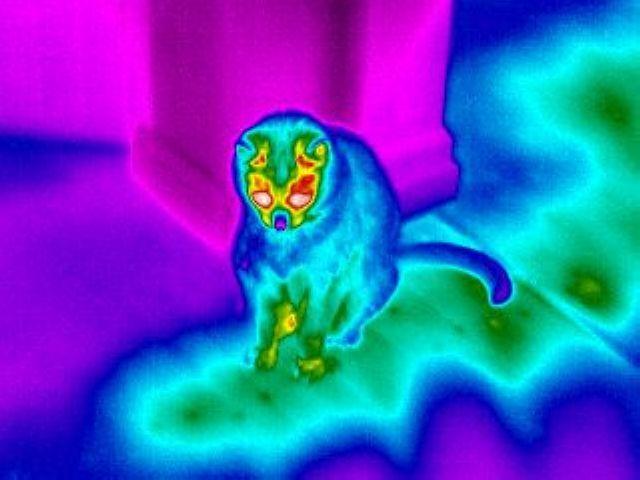

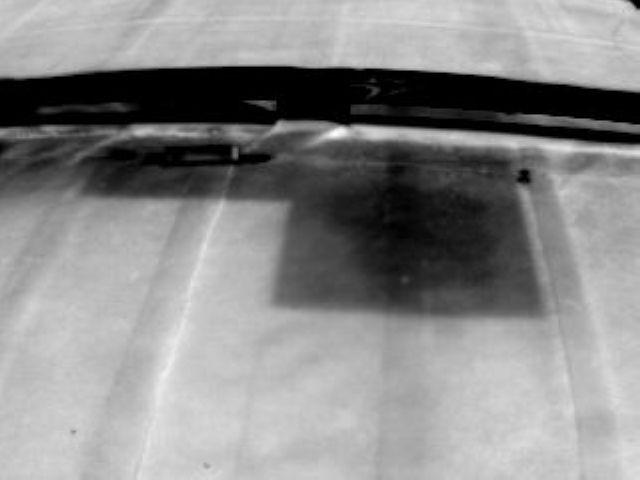

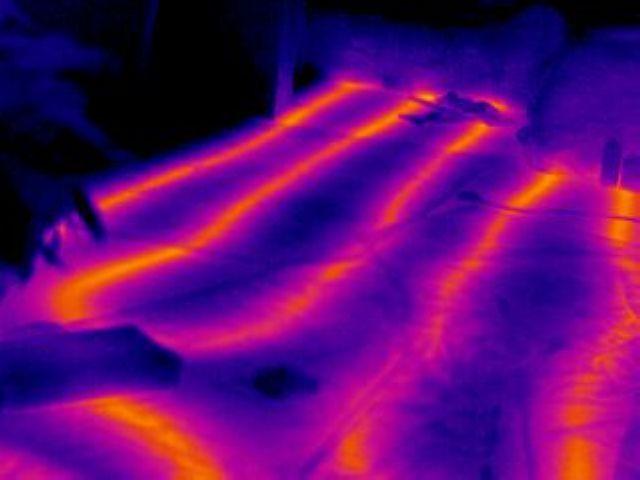

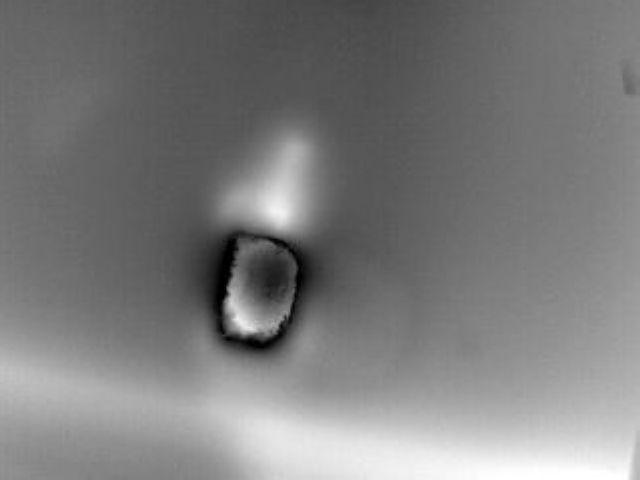

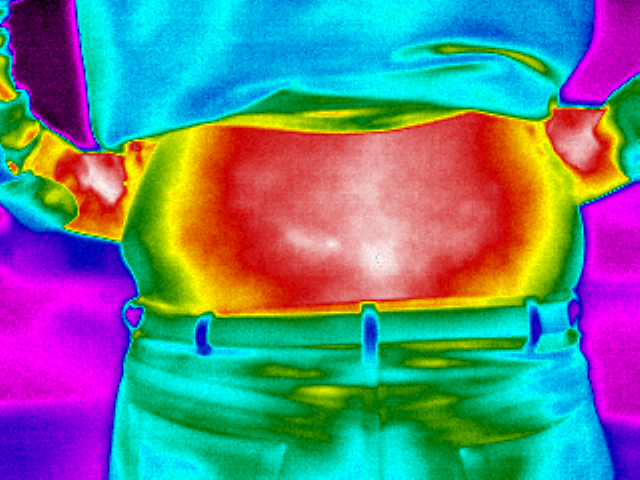

Diagnostic Thermography Photos

Animal sciences can benefit from the usage of thermography that can be used in diagnostics.

Infrared Thermography Applications

WHAT SETS MAVERICK APART FROM ALL OTHERS?

Application diversity is one reason why many companies value Infrared Thermography as a key component of their Predictive and Preventative Maintenance Programs. Most applications require certain skills, experience, and special accessories for accurate thermographic surveying and monitoring

Infrared technology is used extensively in industrial and manufacturing facilities for troubleshooting, monitoring, and trending equipment, processes, and systems. As with Maverick’s other technology, the data can be interpreted in real time for many applications, and is often loaded into software for more advanced analysis and reporting.

At Maverick Inspection, we take pride in offering comprehensive infrared thermography services backed by our extensive experience and training. We understand the importance of diligent equipment selection, precise data gathering, thorough software analysis, comprehensive reporting, and effective communication of results. With our expertise, we possess the qualifications and meet the requirements necessary to access even the most secure and demanding sites and facilities.

Our commitment to safety, quality, and reliability goes beyond just training, experience, and data gathering procedures. When you choose Maverick Inspection, you are investing in a trusted partner with the expertise and knowledge to deliver reliable and accurate results.

INFRARED

THERMOGRAPHY

APPLICATION PHOTO GALLERY

- Identifying problem areas in electrical and mechanical systems

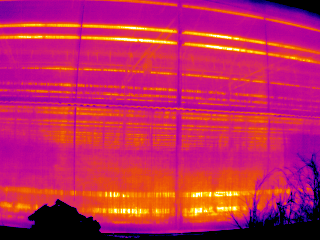

- Analysing building envelopes and membrane systems

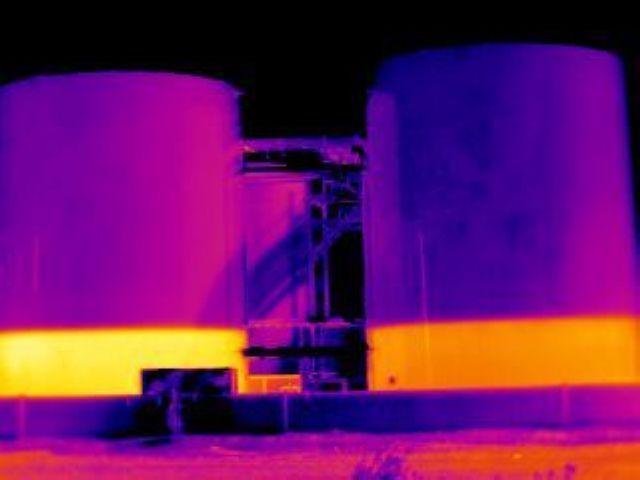

- Troubleshooting industrial process and storage systems

- Specialized utility locates such as in-floor heating systems

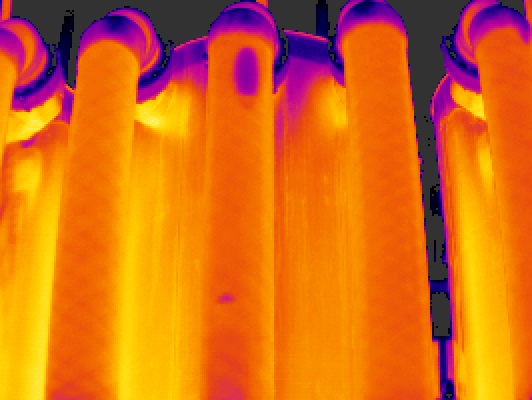

- Furnace and boiler refractory surveys

- Research and development data collection

Call for Information:

780-467-1606

Electrical Thermography Applications

- Indoor Electrical

- Outdoor Electrical

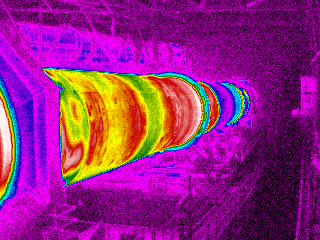

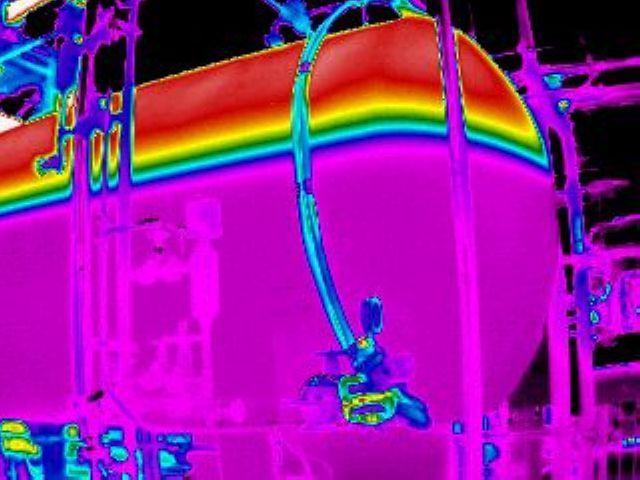

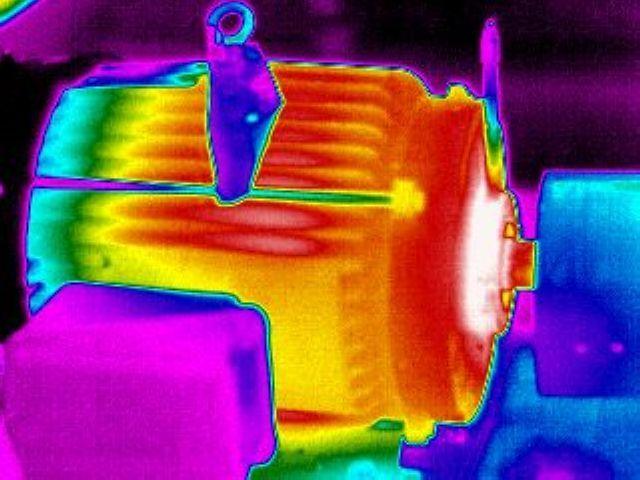

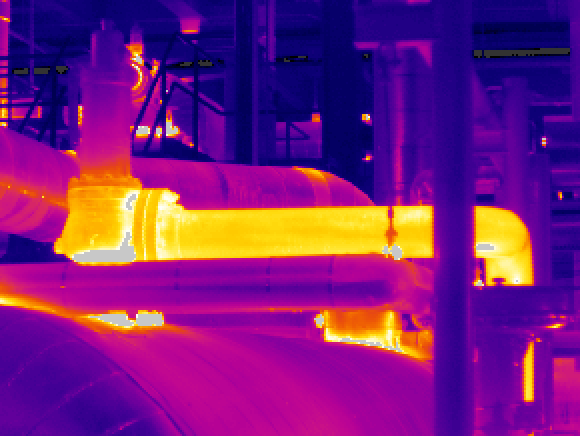

Industrial Infrared Thermography Applications

- Furnaces

- Boilers

- Storage Tanks

- Pressure Safety Valves

- Piping

Building Maintenance Thermography Applications

- Rotating equipment

- Steam systems

- Building envelopes

Maverick Inspection is often involved in Research and Development projects. This includes:

- helping clients set up equipment and procedures for in-house testing

- field-testing new inspection systems

- developing and modifying custom inspection systems

- providing data-gathering support for product or process development

- developing custom solutions for client inspection applications

F.A.Q.

Can you see through walls with an infrared camera?

Infrared cameras are designed to measure the longwave infrared spectrum, which includes the thermal radiation emitted and reflected by objects or surfaces. While some transparent materials may allow longwave infrared to pass through, the majority of objects emit and reflect infrared light, making it possible for infrared cameras to capture and detect thermal energy.

What is Emissivity?

Emissivity is a term used to describe the ability of a surface to emit thermal radiation. It is a measure of how well a surface can radiate heat compared to a perfect blackbody radiator, which has an emissivity value of 1. Emissivity is typically expressed as a value between 0 and 1, where a higher value indicates a surface that efficiently emits thermal radiation. Surfaces with high emissivity, such as rough or matte surfaces, are good at radiating heat, while surfaces with low emissivity, such as shiny or reflective surfaces, are less effective at emitting heat. Emissivity plays a crucial role in infrared thermography as it affects the accuracy of temperature measurements taken with infrared cameras.

Can I detect thermal anomalies through reflective surfaces like aluminum cladding?

Yes, it is possible to detect thermal anomalies through aluminum cladding using thermal imaging technology. Aluminum is a relatively good conductor of heat, and thermal imaging cameras can detect temperature variations on the surface of the cladding. By capturing infrared radiation emitted by the cladding, thermal imaging cameras can identify areas that exhibit different temperatures than the surrounding areas. These temperature variations can indicate potential issues such as insulation gaps, water intrusion, or heat loss. By conducting a thermal inspection of aluminum cladding, thermal anomalies can be detected and addressed to ensure the integrity and energy efficiency of the building envelope.

I require an thermography inspection for insurance purposes. Can you complete this inspection for us?

Yes! We would need to have the facilities made available to our technician, where they would be accompanied by a person familiar with the location and layout of the building systems.

How long does a thermal inspection take?

The duration of a thermal inspection can vary depending on the size and complexity of the asset being inspected, as well as the number of areas that need to be assessed. For example, a basic inspection of a residential home may take a few hours, while a more comprehensive inspection of a large industrial facility could take several days or even weeks. The inspection time can also be affected by factors such as accessibility and weather conditions. It is best to consult with a professional thermographer to get a more accurate estimate of the inspection duration for a specific asset.

Related Services

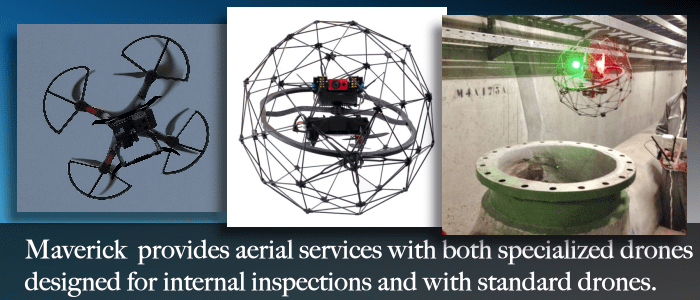

Drone, RPAS and Unmanned Aerial Vehicles

Use drones to navigate into spaces that are inhospitable to manned entry.

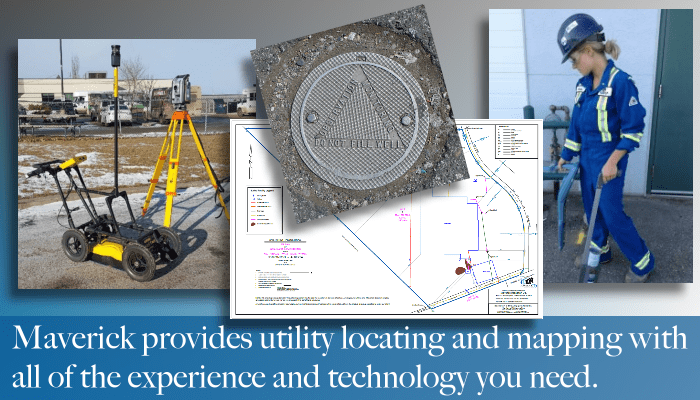

Utility Locating

Between Industrial, commercial and residential utility located Maverick Inspection Ltd. has the experience to get the job done right.

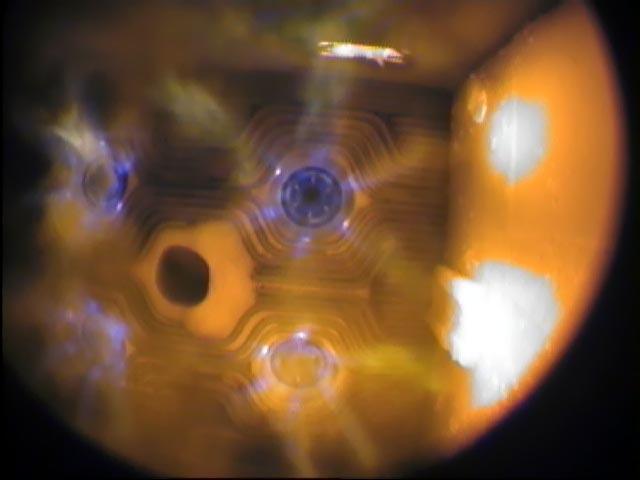

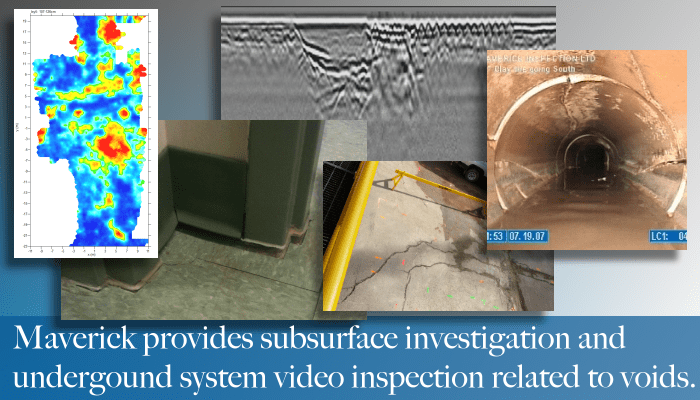

Remote Video Inspection

Use remote video inspection to enhance your sub surface inspection.