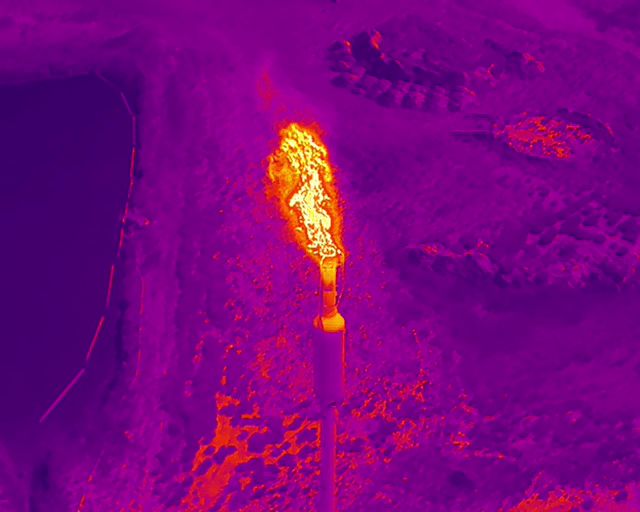

Maverick Inspection Ltd. is a trusted provider of Infrared Thermography services. With a commitment to excellence, we utilize cutting-edge technology, including FLIR cameras integrated into both our drone and handheld systems, to deliver accurate and reliable thermal inspections. Our highly skilled technicians have undergone extensive training to proficiently conduct thermal inspections across various industries. From furnaces, heaters, buildings envelopes and electrical systems, solar panels, flares and tanks, our comprehensive services cover a wide range of areas. At Maverick Inspection, we are dedicated to helping you identify potential issues, optimize performance, and ensure the utmost safety and efficiency of your assets through our top-notch thermal inspection solutions.

Infrared

Handheld and Aerial FLIR services are available.

External Drone Inspections

Asset Inspections including Flares, Towers, Galleries and Facade Inspections.

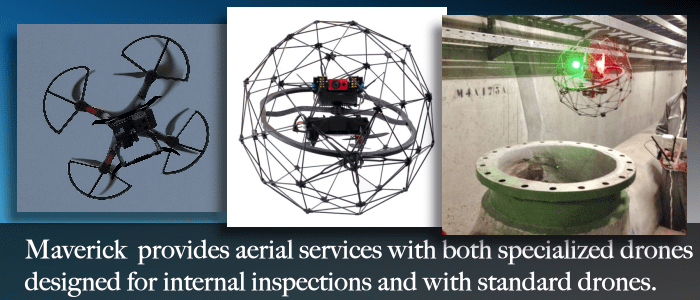

Internal Drone Inspections

Confined Space Inspections for Tanks, Superheaters and Furnaces

Geomatics Mapping and Modeling

Prepare maps in realtime for construction progression and remediation mapping.

Infrared Thermography

WHAT SETS MAVERICK APART FROM ALL OTHERS?

Based in Edmonton, Alberta, Maverick has been providing infrared thermography services in Western Canada since 2001, serving various industries across diverse sites. We possess an extensive range of infrared thermography systems, ensuring we are not limited to a single manufacturer, make, model or deployment platform. It is crucial to understand that each infrared thermography system has its own unique strengths and weaknesses. Our experience and training allow us to select the most suitable option for your specific needs, and in some cases, we can even combine systems or deploy complementary technologies to enhance the inspection process.

At Maverick Inspection, we take pride in offering comprehensive infrared thermography services backed by our extensive experience and training. We understand the importance of diligent equipment selection, precise data gathering, thorough software analysis, comprehensive reporting, and effective communication of results. With our expertise, we possess the qualifications and meet the requirements necessary to access even the most secure and demanding sites and facilities.

Our commitment to safety, quality, and reliability goes beyond just training, experience, and data gathering procedures. When you choose Maverick Inspection, you are investing in a trusted partner with the expertise and knowledge to deliver reliable and accurate results.

INFRARED THERMOGRAPHY INSPECTIONS

Maverick has provided infrared thermography in Western Canada since 2001. This specialized inspection and data-gathering method has been a perfect fit with both our Remote Video Inspection and

Ground-penetrating Radar Departments.The combination of expertise in all of these fields has allowed Maverick to provide complementary data for applications such as building science, industrial processes,

research and development, and specialized utility and subsurface feature locates.

Maverick’s infrared technicians are trained to Level I & II industry standards, and our additional in-house mentoring and training system ensures that expertise, best practices, and application knowledge are shared and continually developed.

Call For a Quote:

780-467-1606

F.A.Q.

Can you see through walls with an infrared camera?

Infrared cameras are designed to measure the longwave infrared spectrum, which includes the thermal radiation emitted and reflected by objects or surfaces. While some transparent materials may allow longwave infrared to pass through, the majority of objects emit and reflect infrared light, making it possible for infrared cameras to capture and detect thermal energy.

What is Emissivity?

Emissivity is a term used to describe the ability of a surface to emit thermal radiation. It is a measure of how well a surface can radiate heat compared to a perfect blackbody radiator, which has an emissivity value of 1. Emissivity is typically expressed as a value between 0 and 1, where a higher value indicates a surface that efficiently emits thermal radiation. Surfaces with high emissivity, such as rough or matte surfaces, are good at radiating heat, while surfaces with low emissivity, such as shiny or reflective surfaces, are less effective at emitting heat. Emissivity plays a crucial role in infrared thermography as it affects the accuracy of temperature measurements taken with infrared cameras.

Can I detect thermal anomalies through reflective surfaces like aluminum cladding?

Yes, it is possible to detect thermal anomalies through aluminum cladding using thermal imaging technology. Aluminum is a relatively good conductor of heat, and thermal imaging cameras can detect temperature variations on the surface of the cladding. By capturing infrared radiation emitted by the cladding, thermal imaging cameras can identify areas that exhibit different temperatures than the surrounding areas. These temperature variations can indicate potential issues such as insulation gaps, water intrusion, or heat loss. By conducting a thermal inspection of aluminum cladding, thermal anomalies can be detected and addressed to ensure the integrity and energy efficiency of the building envelope.

I require an thermography inspection for insurance purposes. Can you complete this inspection for us?

Yes! We would need to have the facilities made available to our technician, where they would be accompanied by a person familiar with the location and layout of the building systems.

How long does a thermal inspection take?

The duration of a thermal inspection can vary depending on the size and complexity of the asset being inspected, as well as the number of areas that need to be assessed. For example, a basic inspection of a residential home may take a few hours, while a more comprehensive inspection of a large industrial facility could take several days or even weeks. The inspection time can also be affected by factors such as accessibility and weather conditions. It is best to consult with a professional thermographer to get a more accurate estimate of the inspection duration for a specific asset.

Does electrical equipment need to be live?

Electrical equipment needs to be under load to experince the full benefits of a thermal inspection. Conductors heat up when current is flowing and points of resistance can cause heat to build. The most common hot spot in a cabinet is an untightened lug, with poor conduction while there is a load. Identify these areas and others, early, before the problem develops into an equipment outage.

Thermography Services

- Electrical System Inspections: We conduct thorough inspections to detect overheating components, faulty connections, and electrical load imbalances in switchgear, electrical panels, motors, and other electrical equipment.

- Mechanical Equipment Inspections: Our team monitors the performance of motors, pumps, bearings, heat exchangers, and other mechanical systems using thermography to detect anomalies, prevent breakdowns, and optimize maintenance.

- HVAC System Inspections: We assess the efficiency of heating, ventilation, and air conditioning systems, detecting air leakage and identifying malfunctioning components to enhance energy efficiency and indoor comfort.

- Roof Inspections: Our thermography services help identify moisture intrusion, insulation gaps, and areas of heat loss in roofs, preventing water damage and improving energy efficiency.

- Energy Audits: We conduct comprehensive energy audits, evaluating energy usage patterns, identifying areas of energy loss, and recommending energy-saving measures for residential and commercial buildings.

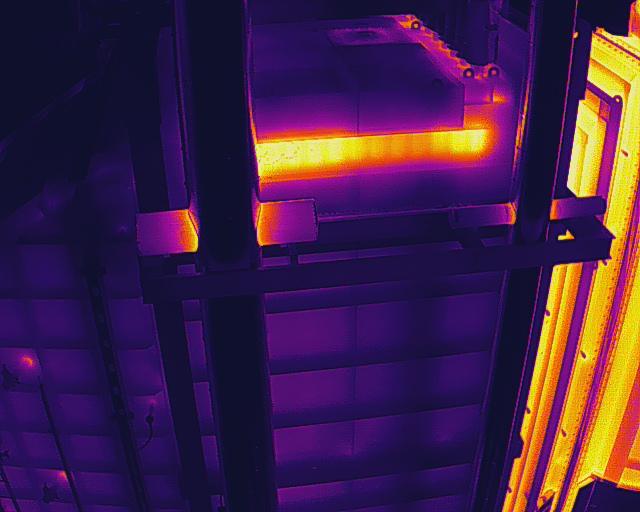

- Industrial Equipment Inspections: Maverick Inspection specializes in monitoring heat distribution, detecting faulty components, and optimizing maintenance of boilers, furnaces, ovens, and other industrial equipment.

- Solar Panel Inspections: Our experts assess the performance of photovoltaic solar panel systems, detecting malfunctioning cells and identifying potential issues to maximize energy production.

- Data Center Inspections: We provide thermography inspections for server rooms and data centers, monitoring temperature distribution and identifying hotspots to ensure optimal equipment performance and prevent downtime.

- Plumbing System Inspections: Our thermography services help detect hidden leaks, assess pipe insulation effectiveness, and identify water flow issues in plumbing systems to prevent water damage and optimize efficiency.

Related Services

Drone, RPAS and Unmanned Aerial Vehicles

Use drones to navigate into spaces that are inhospitable to manned entry.

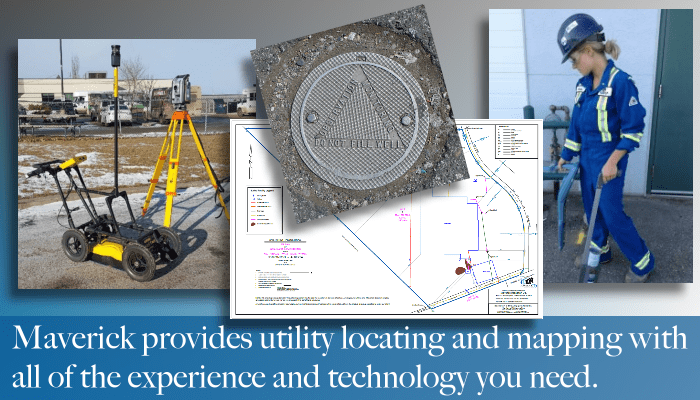

Utility Locating

Between Industrial, commercial and residential utility located Maverick Inspection Ltd. has the experience to get the job done right.

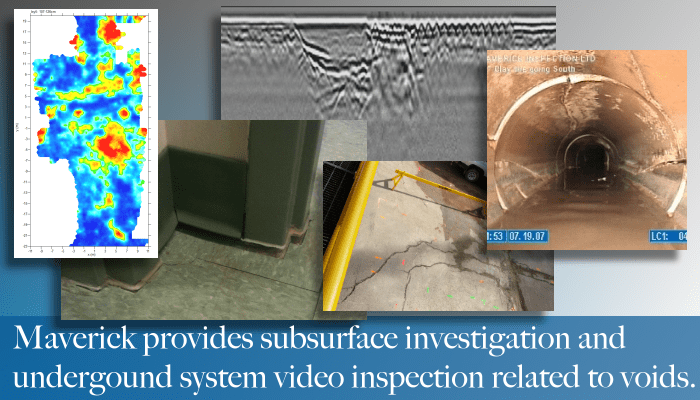

Remote Video Inspection

Use remote video inspection to enhance your sub surface inspection.