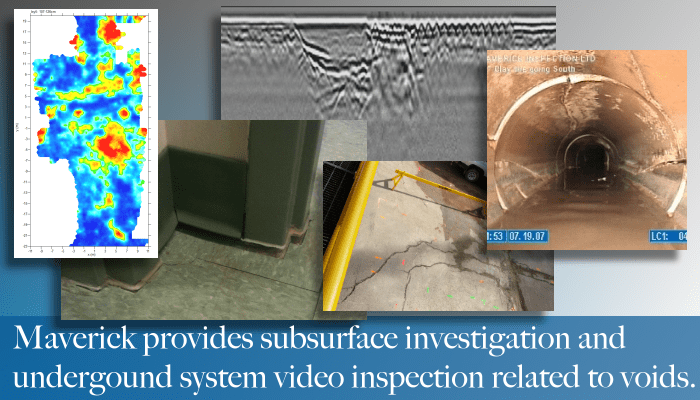

Maverick Inspection Ltd. refers to sub surface investigation as the process of examining and assessing what lies beneath the surface of the ground, typically to locate and identify underground utilities or objects. This investigation involves the use of various technologies and techniques, including ground penetrating radar (GPR), electromagnetic locating, and magnetometry.

Push Reel

Up to 120m in HD

Geomatics Mapping and Modeling

Identify your subsurface utilities with by creating a map or model

Ground Penetrating Radar

Identify buried utilities in real time

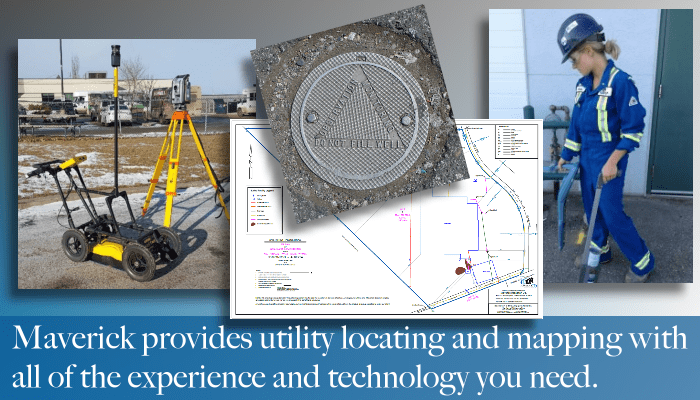

Utility Locating

Direct connect locating with radio detection wand and transmitter

Sub Surface Investigation Applications

Collectively, these technologies: ground penetrating radar, electromagnetic locating, and magnetometry, allow for accurate subsurface investigation and utility locating. They provide valuable insights into the location, depth, and composition of underground utilities, aiding in excavation, construction, and maintenance projects while minimizing the risk of damaging existing infrastructure.

- Ground Penetrating Radar

- Electromagnetic Locating

- Geomatics Mapping and Modeling

- Magnetrometery

- Confined Spaces

Subsurface Investigation Application

GPR Applications cover a wide range of sites, projects, and reporting formats. The quality of remote sensing data relies heavily on the collection procedures, equipment, and post-processing capabilities of the service provider. Maverick uses radar and other systems daily across all industries, locations, and conditions.

Call For a Quote:

(780) 467-1606

Engineering Application

- Location of buried well heads,underground storage tanks, and related facilities for reclamation projects

- Information on concrete structures such as concrete thickness, rebar spacing and placement, void detection, and stirrup locations in beams

- Data gathering for concrete structures such as sulphur pits, skids, pedestals, foundations, and footings

- Pipeline and roadway route data-gathering relating to subsurface obstacles such as boulders and ground water

Reclamation work, environmental engineering and other testing requires the drilling of boreholes. Maverick Inspection Ltd. provides private utility locates, on private property using a combination of EM detection and GPR systems.

Construction Application

- Bridge Construction & Repair

- Retaining Wall Repair

- Concrete Silos, Pits & Tanks

- Floor Thickness Estimates

- Locating Covered Curb Cocks, Drains, Etc.

- Anchor and Duct Installation in Mechanical Rooms

- Elevator Shaft Work

- Installation of Machinery and Lifts in Machine Shops

- Renovation and Construction of Commercial Spaces

- Parkade Ramp Repairs

- Utility Locates in Yard and Parking Areas

- Critical Crane Lifts

Maverick has experience in the shopping malls, office towers and commercial buildings in Edmonton, Red Deer, Calgary, Fort McMurray, and beyond, as well as hospitals, schools, transit centres, parkades, and other sites and structures. Some of the special projects we have worked on have pushed the boundaries of the GPR systems with special requests such as supplying depth of rebar coverage with +/-3 mm accuracy!

Industrial Application

Occupational Health and Safety Regulations require that all underground facilities are located prior to a ground disturbance. Industrial sites often have multiple subsurface systems and structures, and they present unique locating and mapping challenges. Facility-wide utility locates often include:

- Power cables

- Data/communication and control cables

- Utilities including natural gas and propane lines

- Process lines

- Cathodic protection systems, and associated lines

- Metallic and non metallic lines including HDPE, AC/Ductile, Fibreglass, PVC and ABS

- Drainage and fire water systems

- Underground storage tanks

Maverick provides field markings of located items and can provide CAD and GIS reporting for updating site plans.

Concrete Application

- Office Towers – Concrete scanning is often used to identify the location of rebar, Q-deck plates, beams, conduits, pipes and other buried infrastructure during renovations.

- Shopping Centres and Strip-Malls – Concrete scanning of often used to detect objects buried beneath slab-on-grade concrete pads during renovations and repairs.

- Hospitals – GPR Concrete Scanning can be used around patients, staff and equipment with minimal disruption to the workflow. GPR will also not destroy X-ray film.

- Schools and Universities – GPR Concrete Scanning can be used in active buildings without disrupting the students or teachers.

- Transit Centres – Maverick has deployed our Concrete Scanning GPR systems in busy transit terminals without disrupting transit service. We often locate rebar and conduits prior to the installation of new electrical or communications devices.

- Bridge Decks, Piers, Columns and Spans – As part of a maintenance cycle, or as part of Quality Assurance, Maverick Inspection Ltd. has provided information to project managers and engineers regarding the presence, spacing and placement of critical reinforcement steel members in several bridges using our GPR/Concrete Scanning systems.

- Machine Shops – Prior to moving existing equipment or adding new equipment, Maverick has been asked to provide Concrete Scanning/GPR services in order to locate existing buried electrical systems, communication lines, fire-alarms and pneumatic/hydraulic lines.

- Laboratories – Lab equipment is constantly changing and labs are constantly being updated. Maverick has often performed Concrete Scanning/GPR prior to the installation of new equipment involving the use of cores through existing block walls and concrete floors.

Archaeological Application

Burials, artefacts, and other cultural and archaeological finds are sensitive and valuable. Ground-penetrating Radar and other subsurface investigation and mapping tools help stakeholders carefully and diligently preserve sites. Maverick has worked across Canada and globally on locations ranging from tundra to tropical islands, and on scopes ranging from locating a single grave site to mapping entire areas.

- Working closely with cemeteries in order to update their records, and maximize their use of space without disturbing older unmarked graves.

- Working with archaeologists to locate building foundations and other targets of archaeological interest during pre-construction phases of oilfield projects.

- Working with municipalities and First Nations to map out burials prior to development projects.

- Providing information to various policing agencies regarding the use of Ground-penetrating Radar for locating objects ranging from stolen goods to murder weapons and missing persons. Performing consulting work on documentary films, and including direct on-set involvement and in pre-production planning.

- Working with non-profit organizations to locate WWII individual and mass graves for repatriation of remains.

- Mapping out potential meteor impact craters.

-

Related Services

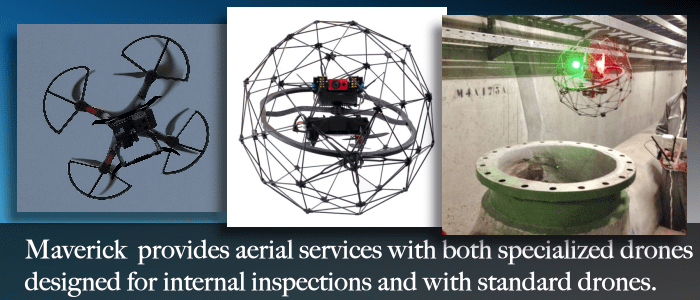

Drone, RPAS and Unmanned Aerial Vehicles

Use drones to navigate into spaces that are inhospitable to manned entry.

Utility Locating

Between Industrial, commercial and residential utility located Maverick Inspection Ltd. has the experience to get the job done right.

Remote Video Inspection

Use remote video inspection to enhance your sub surface inspection.

F.A.Q.

Every job has it’s own unique aspects. Fill us in on some details.

What is Subsurface Investigation?

Subsurface investigation, also known as site investigation or geotechnical investigation, is a process of gathering information about the characteristics, properties, and conditions of the ground beneath the Earth’s surface. This investigation is conducted to understand the geological, hydrogeological, and geotechnical aspects of a site. The information obtained from subsurface investigation is crucial for a wide range of applications, including construction, engineering, environmental assessment, resource exploration, and more

Why is Subsurface Investigation Important?

- Structural Safety: Subsurface investigation provides critical information about soil stability, load-bearing capacity, and geological conditions. This knowledge is essential for designing structures that are safe, stable, and resilient to natural forces such as earthquakes, landslides, and soil erosion.

- Foundation Design: Proper foundation design is crucial for the stability of any structure. Subsurface investigation helps engineers determine the most suitable foundation type and depth, ensuring that structures are built on solid ground that can support the intended load.

- Risk Mitigation: Subsurface investigation identifies potential risks, such as contaminated soil or unstable ground, allowing project planners to implement appropriate measures to mitigate these risks and avoid costly issues during construction or operation.

- Cost Efficiency: Accurate information from subsurface investigation helps prevent unexpected surprises during construction. By understanding the subsurface conditions beforehand, project budgets can be more accurately estimated, minimizing the risk of cost overruns.

- Environmental Protection: Subsurface investigation is crucial for identifying contaminants and pollutants in the soil and groundwater. This information is essential for ensuring that construction and development activities do not adversely affect the environment and human health.

- Regulatory Compliance: Many construction and development projects are subject to regulations that require thorough subsurface investigation to assess potential impacts on the environment and surrounding areas. Compliance with these regulations is necessary for obtaining permits and approvals.

- Optimized Design: Subsurface investigation data allows designers to tailor their plans to site-specific conditions. This optimization leads to better designs that account for soil properties, groundwater levels, and other factors, resulting in more efficient and effective projects.

- Infrastructure Planning: Subsurface investigation aids in locating existing utilities and infrastructure beneath the ground. This information prevents accidental damage during construction, reducing disruption and repair costs.

- Construction Planning: Subsurface investigation provides insights into the challenges and complexities of construction in certain areas. This helps in planning construction methods and scheduling work effectively.

- Geological Understanding: Subsurface investigation contributes to a deeper understanding of geological formations, which is valuable for geological research, resource exploration, and mapping geological history.

- Long-Term Durability: Proper subsurface investigation ensures that structures are designed to withstand the unique conditions of a particular location, leading to longer-lasting and more durable buildings and infrastructure.

- Avoiding Litigation: Accurate subsurface investigation can prevent legal disputes arising from unexpected construction issues. When parties have a clear understanding of subsurface conditions, potential conflicts can be minimized.

- Project Success: Ultimately, subsurface investigation is integral to project success. It lays the foundation for informed decision-making, reduces uncertainty, and contributes to the overall quality, safety, and success of construction, development, and environmental projects.

What Techniques are Used in Subsurface Investigation?

- Drilling Methods:

- Auger Drilling: Uses rotating helical blades to excavate soil and retrieve samples from shallow depths.

- Percussion Drilling: Involves repeatedly dropping a heavy bit to break and remove soil, suitable for harder formations.

- Rotary Drilling: Employs a rotating bit to bore into the ground, often used for deeper exploration and rock sampling.

- Coring: Collects cylindrical rock or soil samples using a core barrel, providing relatively undisturbed samples for analysis.

- Geophysical Surveys:

- Ground Penetrating Radar (GPR): Uses radar pulses to detect variations in subsurface materials and structures.

- Seismic Refraction: Measures the time it takes for seismic waves to travel through the ground, helping determine subsurface layers’ depths and velocities.

- Electrical Resistivity Imaging: Measures electrical resistance to map variations in soil and rock properties.

- Magnetic and Gravity Surveys: Detect variations in the magnetic and gravitational fields caused by subsurface materials.

- Soil Sampling:

- Standard Penetration Test (SPT): Measures the resistance of soil to penetration, providing insights into soil properties and bearing capacity.

- Cone Penetration Test (CPT): Measures the cone resistance and sleeve friction as a cone is pushed into the soil, offering information on soil strength and stratification.

- Borehole Logging:

- Natural Gamma Ray Logging: Measures natural radiation emitted by subsurface materials to identify different rock types.

- Sonic Logging: Measures the speed of sound waves in boreholes to assess rock density and mechanical properties.

- Electric and Acoustic Logging: Measures electrical and acoustic properties of formations to determine lithology and porosity.

- Remote Sensing:

- Lidar: Uses laser beams to create detailed 3D maps of the surface, helping identify surface features that might indicate subsurface conditions.

- Satellite and Aerial Imagery: Analyzes satellite and aerial photographs to identify surface features, topography, and potential geological structures.

- Test Pits and Trenches:

- Test Pits: Excavates shallow holes to visually examine and sample soil and rock layers.

- Trenches: Provides a larger cross-sectional view of subsurface layers, often used in archaeological or construction site investigations.

- Remote Sensing and Geospatial Analysis:

- Ground-based LiDAR: Scans the surface to create detailed topographic maps and identify surface features.

- Photogrammetry: Uses photographs to create accurate 3D models of the terrain, helping to analyze surface changes and deformations.

- Hydrogeological Testing:

- Pumping Tests: Measures water levels and rates during controlled pumping to determine aquifer properties.

- Slug Tests: Involves introducing a small amount of water into a well and measuring the resulting water level response.

- Laboratory Testing:

- Soil Classification: Determines soil type and properties through tests like grain size analysis and Atterberg limits.

- Rock Testing: Measures mechanical properties like strength, deformation, and durability.

What Information Can Subsurface Investigation Provide?

- Soil Composition and Properties: Subsurface investigation reveals details about the type of soil present, including its texture, density, cohesion, and permeability. This information is essential for designing foundations, earthworks, and retaining structures.

- Geological Formations: It helps identify the geological formations present in the subsurface, such as rock layers, fault lines, and mineral deposits. This knowledge is vital for geologists, engineers, and environmental scientists.

- Groundwater Levels and Flow: Subsurface investigation provides data on groundwater levels, flow direction, and aquifer properties. This is crucial for designing effective drainage systems, managing water resources, and assessing potential impacts on nearby water bodies.

- Contaminant Presence: It identifies the presence of contaminants or pollutants in the soil and groundwater, aiding in environmental assessments and remediation planning. This information is crucial for ensuring human health and environmental protection.

- Load-Bearing Capacity: Subsurface investigation assesses the load-bearing capacity of soil, which is critical for designing foundations, determining allowable building loads, and ensuring the stability of structures.

- Subsurface Stability: Information about soil stability, potential for landslides, and soil erosion risks helps in assessing the safety of construction sites and designing appropriate stabilization measures.

- Construction Challenges: Subsurface investigation reveals potential challenges during excavation, such as hard rock layers, waterlogged soil, or buried obstacles like boulders or old infrastructure.

- Seismic Vulnerability: Understanding subsurface conditions helps assess the potential impact of earthquakes on a construction site. This information is essential for designing earthquake-resistant structures.

- Utility and Infrastructure Mapping: Subsurface investigation can locate existing underground utilities and infrastructure, reducing the risk of damage during construction.

- Drainage and Percolation: Data on soil permeability and drainage properties influence the design of stormwater management systems and wastewater disposal methods.

- Materials for Construction: Information about the availability of suitable construction materials (such as aggregates) in the subsurface can influence project design and minimize transportation costs.

- Archaeological and Historical Significance: Subsurface investigation can uncover artifacts, ancient structures, or historical layers, contributing to archaeological research and heritage preservation.

- Environmental Impact Assessment: It aids in assessing the potential impacts of a project on the environment, helping developers and regulatory bodies make informed decisions.

- Site Characterization: Overall, subsurface investigation provides a comprehensive characterization of a site’s physical and geological attributes, which is critical for informed decision-making in various industries.

How does Subsurface Investigation Impact Project Design and Planning?

- Foundation Design and Stability: Subsurface investigation provides critical information about soil composition, strength, and stability. This data helps engineers design appropriate foundations that can support the structure’s load and prevent issues like settling, shifting, or structural failure.

- Geotechnical Engineering: Subsurface investigation aids in understanding the geological conditions of a site. This knowledge is essential for designing structures, such as retaining walls, embankments, tunnels, and bridges, that can withstand the natural forces present in the area, like soil erosion, earthquakes, and landslides.

- Environmental Assessment: Subsurface investigation identifies potential contaminants, pollutants, or hazardous materials in the soil and groundwater. This information is vital for assessing environmental risks and planning remediation measures to prevent contamination spread, ensuring compliance with regulations.

- Utility Placement and Infrastructure: Subsurface investigation helps identify the location of existing utilities, pipelines, and underground infrastructure. This knowledge is crucial to avoid disruptions during construction, reducing the risk of accidental damage to these utilities.

- Cost Estimation: Accurate subsurface information enables better cost estimation for a project. It helps account for factors like excavation difficulty, soil stabilization requirements, and foundation design complexities, leading to more precise budget projections.

- Risk Mitigation: By understanding the subsurface conditions, potential risks associated with the project can be anticipated and mitigated. For instance, areas prone to landslides or soil liquefaction during earthquakes can be identified and addressed in the design phase.

- Project Timeline: Subsurface investigation informs project timelines by providing insights into potential delays caused by challenging soil conditions, unexpected contaminants, or complex geological formations. This helps in setting realistic project schedules.

- Regulatory Compliance: Subsurface investigation ensures compliance with regulations and permits related to construction, environmental protection, and land development. It helps identify potential legal or environmental obstacles early in the planning stage.

- Design Optimization: The data from subsurface investigation can be used to optimize design choices. For example, understanding groundwater levels can influence building heights, basement design, and drainage systems.

- Long-Term Durability: Incorporating subsurface investigation data into project planning increases the durability of structures by tailoring designs to the specific site conditions. This ensures that the constructed facility can withstand environmental challenges for its intended lifespan.