The Right Technology and Experience

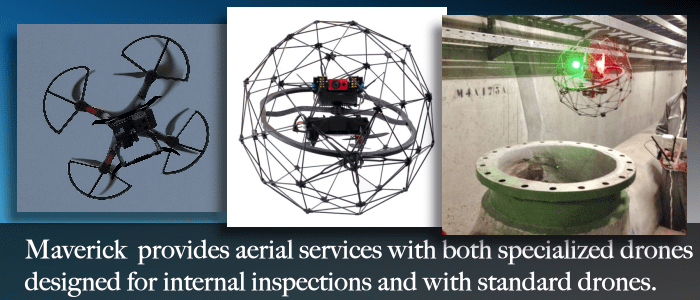

Maverick Inspection Ltd. benefits clients by offering a wide range of equipment and experience, completing hundreds of flight operations in Western Canada every year. Our service focus ranges from operation of confined space drone systems to the collection of detailed geospatial data. Remotely operated inspection technologies are gaining widespread use in many different industries, and the RPAS team leverages their experience to assist with your project. Significant time and cost savings can be realized when the right technology is implemented by experienced professionals. Increase safety for personnel by eliminating the need for confined space entry teams, rescue teams, and scaffolding.

Confined Space Inspections

Our technicians have the training and experience to successfully operate drones in sumps, tanks, rafters, furnaces, basins, pipelines, storm drains, and more.

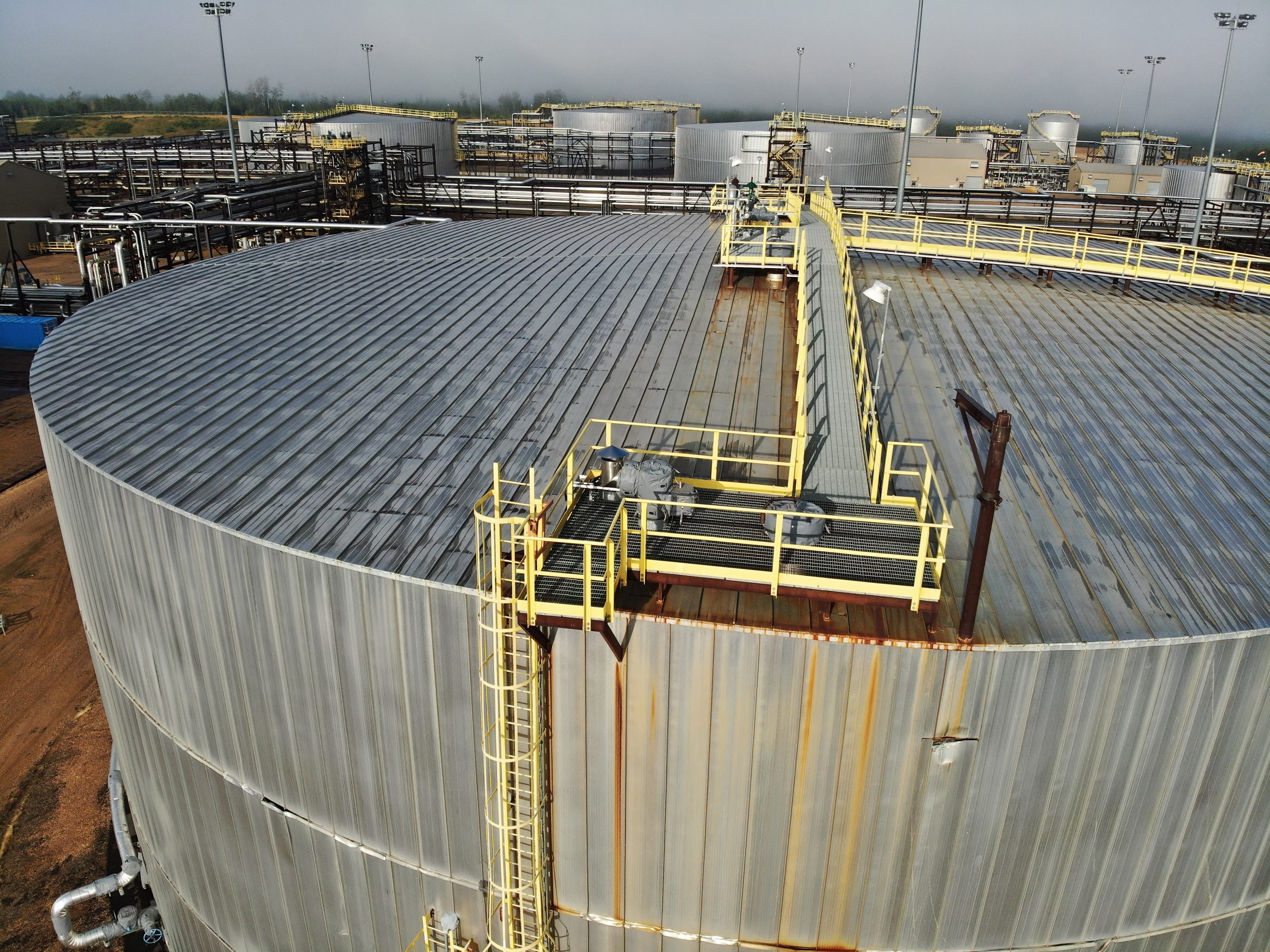

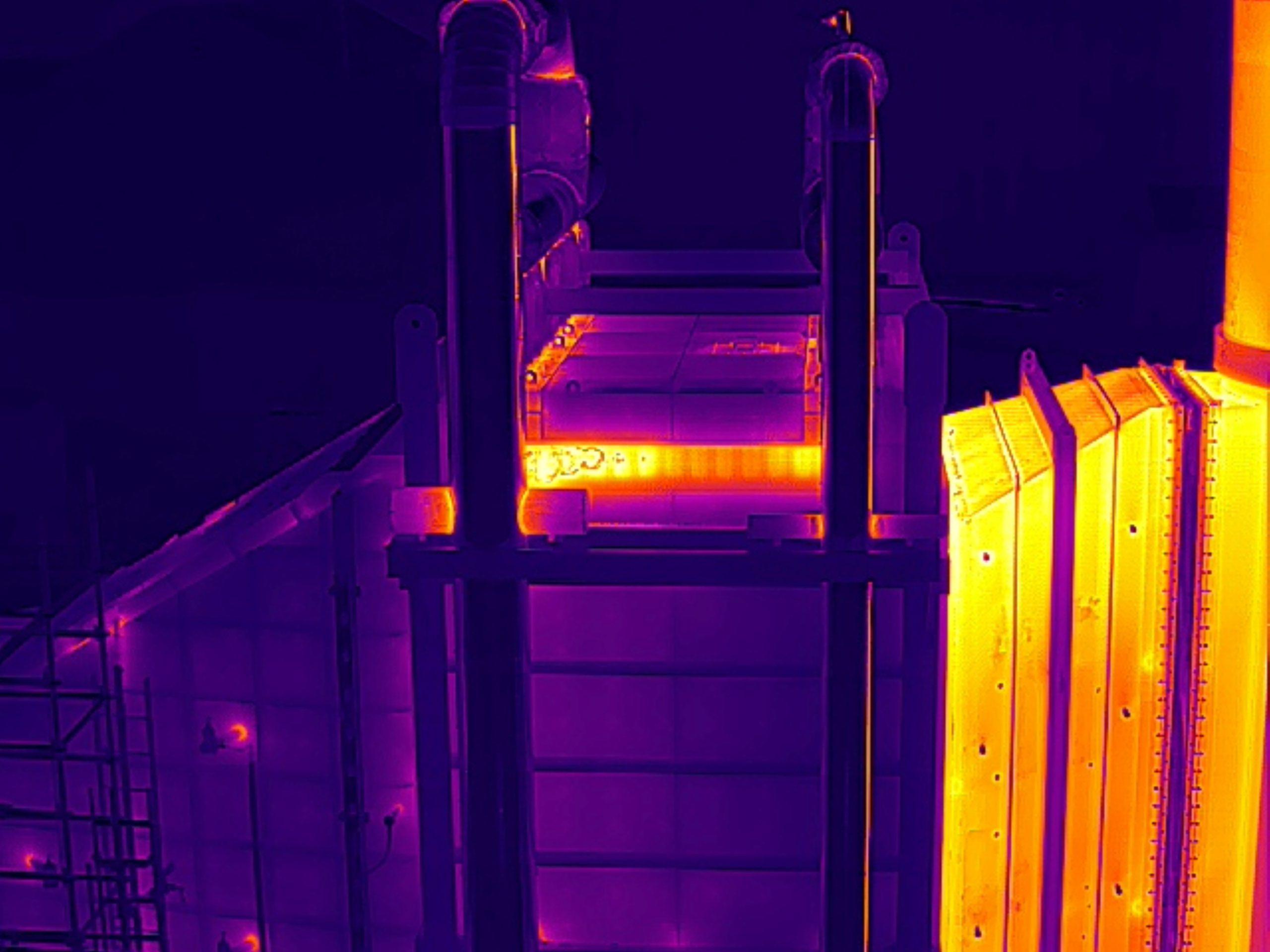

External Visual & Thermal Inspections

High-resolution cameras collect data of flares, towers, exhaust stacks, furnaces, galleries, and building envelopes from safe standoff distances. Infrared cameras inspect roofing systems, flare pilots, refractory integrity, and solar panels.

Detailed Summary Reporting

We specialize in data presentation and tailor reports to fit the needs of your organization. Data remains strictly confidential and is transferred to your organization post-collection.

Geomatics Mapping & Modeling

Data is post-processed into high-quality deliverables that are referenced to the location where they were obtained.

Western Canada’s

Drone Service Provider

Industrial Drone Inspection Systems

Industrial drone inspections require specialized equipment, specific training, and precise procedures, setting them apart from the operations popular among hobbyists and other users. With decades of experience in providing inspection services for Alberta industry, Maverick understands the diligence and professionalism required for this field.

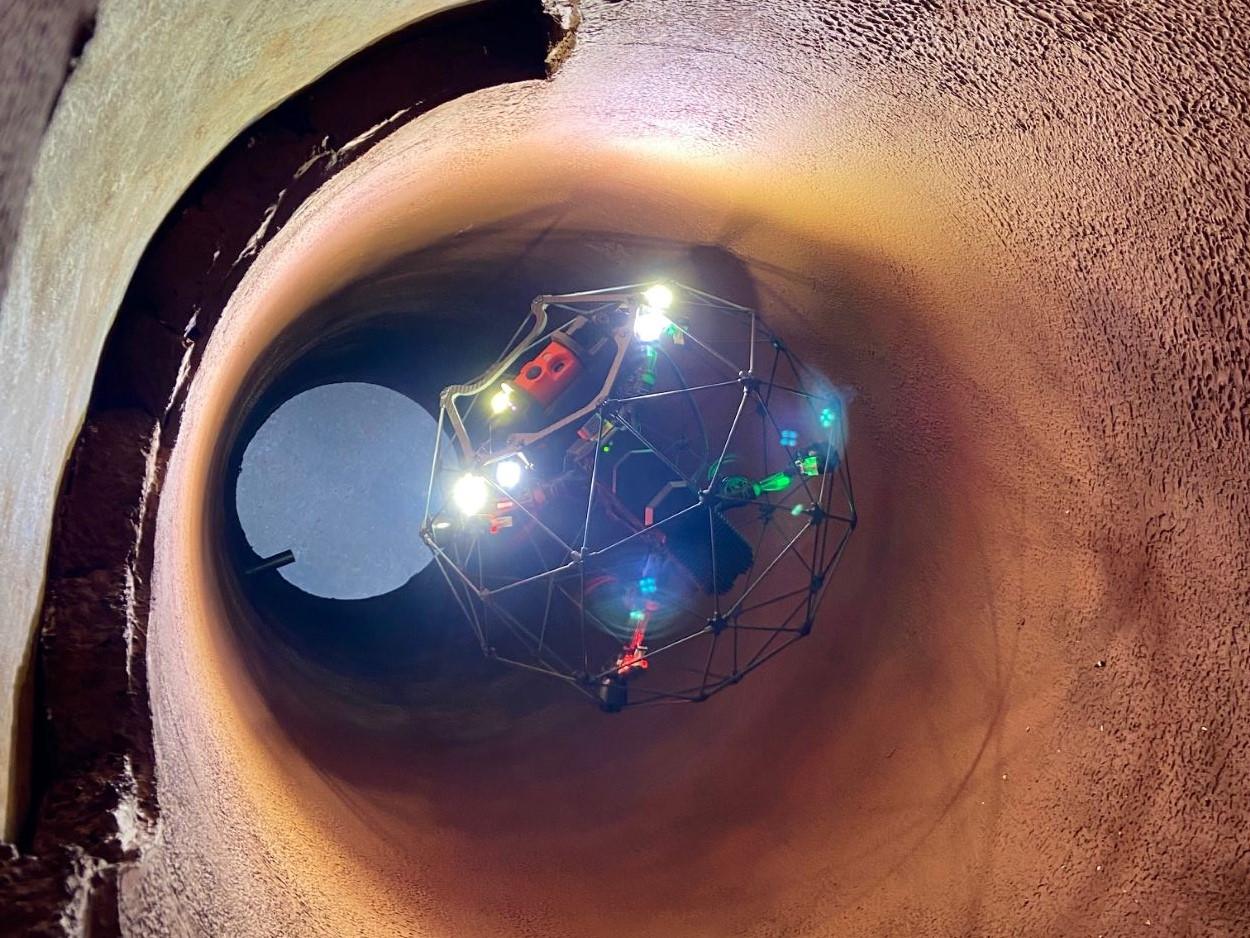

For internal drone inspections, Maverick utilizes Flyability’s ELIOS 2 drone. Engineered to ensure safe and effective video inspections of plant equipment internals, the ELIOS 2 is designed to be collision-tolerant, making it ideal for assessing stacks, chimneys, vessels, piping, and other industrial internal structures.

Additionally, Maverick offers traditional aerial drone inspections for various everyday applications such as roof scans, building envelopes, and aerial mapping. When combined with Maverick’s CAD, GIS, geomatics, and mapping capabilities, drones become powerful tools that go beyond being mere gadgets or toys.

30 Years of Remote Video Inspection

Maverick Inspection has been in buisness for over 30 years and serves industry as a specialized service vendor for inspection systems across Western Canada. Our pilots lead the industry, specializing in complex flight operations. We typically deploy a two man team into the field to enhance the safety and efficiency of traditional drone inspections and data collecting. Our RPAS teams fully comply with the Canadian Aviation Regulations that govern the external operation of remotely piloted aircraft systems in Canadian airspace. They use enterprise grade systems that have advanced capabilities beyond consumer or hobbyist grade drones.

Call for Information:

780-467-1606

DRONE INSPECTION APPLICATIONS

- Confined space inspections of tanks, vessels, piping, stacks, chimneys, process equipment, headers, pipelines, subsurface vessels, sinkholes, and storm drains.

- Thermal imaging of roofs, tanks, vessels, and building envelopes.

- Aerial imaging and mapping of site infrastructure, pipelines, and right-of-ways.

- Creation of maps, digital surface models, digital elevation models, digital terrain models, point clouds, and 3D models.

- Automated routine inspections.

- Methane leak detection, as well as other VOCs.

- Visual inspection of infrastructure including bridges, manways, platforms, ladders, and decks.

- Flare inspections.

- Building envelope inspections.

- Solar panel inspections.

Maverick Inspection Ltd., headquartered in Alberta, operates a fleet of inspection RPAS for a wide range of internal and external applications. These UAVs are equipped with state-of-the-art, enterprise-level technology, making them among the most advanced equipment available on the market. Technicians follow a comprehensive RPAS operations program, which combines well-established procedures in mission planning, operations, and data processing. Maverick Inspection Ltd. ensures compliance with the Canadian Aviation Regulations that govern Canadian airspace through its RPAS operations program.

Maverick Inspection understands the needs and requirements of Alberta’s industrial sites. We are a local company that has provided inspection services across Western Canada since 1994.

TANKS AND SILOS

Drones, such as Flyability’s Elios 2, offer immense value for conducting inspections in confined spaces, particularly within the internal parts of tanks. These inspections play a crucial role in identifying signs of in-service damage, such as coating damage, oxidation, corrosion, and material buildup. By utilizing drones for confined space inspections, the risk to entrants is significantly reduced, and the need for scaffold construction is minimized. Moreover, the valuable information obtained from drone inspections enhances the efficiency and effectiveness of maintenance tasks.

Equipped with advanced capabilities, the Matrice 300 RTK drone excels at navigating around the outside of tanks at a safe distance while capturing high-resolution imagery and video footage of the tanks. This enables inspectors to remotely assess and analyze the condition of external components without entering tank berms and restricted access areas. As a result, safety is greatly enhanced, while saving valuable time and resources compared to traditional inspection methods.

FURNACES AND PROCESS HEATERS

By incorporating the DJI Matrice 300 RTK drone into furnace and process heater inspections, companies can effectively mitigate risks associated with approaching live equipment, while minimizing downtime during maintenance and inspection activities. The drone’s maneuverability and advanced imaging capabilities ensure thorough inspections, optimizing both time and resources for the organization.

The Elios 2 drone offers exceptional capabilities for conducting detailed internal inspections of refractory and insulation materials in furnaces and process heaters. These areas are commonly prone to concerns and require careful evaluation. With its ability to capture high-resolution imagery and video, the Elios 2 drone provides a close-up view of critical components such as tubing, anchors, inlets, piping, manways, refractory bricks, and cast refractory materials. This enables inspection teams to quickly and accurately identify signs of damage, wear, or degradation.

CONFINED SPACES

Confined space inspections can be effectively conducted using remote video inspection technologies, including drones or UAVs. Concrete basins, sumps, surge tanks, and underground infrastructure can all be inspected with the assistance of drones. By utilizing drones, the need for manned entry into these spaces is eliminated, enhancing safety and reducing risks associated with human exposure. Drones provide high-resolution 4K videos and images from inside the structures, enabling detailed assessments of their condition. Opt for drone inspections to de-risk infrastructure assessments and ensure efficient, safe, and comprehensive evaluations of confined spaces.

By incorporating drones into confined space inspections, companies can elevate their inspection processes, prioritize worker safety, and acquire crucial information for maintenance planning and decision-making.

DRONE THERMAL INSPECTIONS

The DJI Matrice 300 RTK, when equipped with a thermal camera, serves as an exceptional tool for conducting thermography inspections on diverse assets. It excels in assessing the condition of solar panels, furnaces, flare stacks, and transmission lines through precise thermal imaging. Moreover, the Matrice 300 RTK offers valuable applications in building envelope inspections, including windows and doors, evaluating wall insulation performance, and assessing roofing insulation effectiveness.

F.A.Q.

Can you inspect confined spaces with a drone?

Yes, drones are very useful in inspecting confined spaces because they reduce risks to personnel and require minimal rescue and scaffolding for access. There are additional considerations, such as the requirement for a non-explosive and relatively clean or dry atmosphere. The drone can navigate as far as radio reception and battery endurance allow. Lighting and advanced navigational aiding sensors are onboard the drone.

How far can a drone fly?

Typically, a remotely piloted aircraft system or drone is limited by battery endurance and radio reception. Additionally, Canadian Aviation Regulations (CARs) require that a drone be flown within visual line of sight (VLOS). Battery capacity and radio reception also apply to internal operations. However, in confined spaces, the signal may drop around sharp corners, and it also depends on the materials that make up the space. The maximum service ceiling for an RPAS is 120m above ground level in Canada.

What types of data can we collect with a remotely piloted aircraft system?

We can collect many different data types. To the Maverick RPAS team, drones are tools for collecting data from unique spaces. If a payload can be integrated onto a drone, we can operate it. Cameras, LIDAR, infrared cameras, multispectral sensors, acoustic sensors, sonar sensors, methane detectors, ground-penetrating radar, and magnetometry are all part of the sensor payloads we can integrate. Afterward, the data is simply referenced to its position in space and time. Numerous deliverables can be produced from the collected data, and we are always seeking new ways to meet clients’ requirements.

Can you fly over people?

Yes, the systems we use have specific operating characteristics that allow for operation over people in certain situations. The Canadian Aviation Regulations define which aircraft can operate over people and when it is acceptable to do so.

However, we work very carefully to control the risk profile of flights. As a general rule, we do not operate over people when there is an alternative. We control the workspace and set up flagging and barricades around the inspection area to maintain focus on operations. Whenever possible, we select a flight profile that aligns with CARs and minimizes associated risks.

My inspection area is close to an airport. Are you allowed to operate close to an airport or heliport?

Flight operations and RPAS inspections close to airports are conducted by pilots who hold Advanced ratings on their RPAS pilot’s certificate. Additionally, the aircraft systems used are approved by Transport Canada for operation in controlled airspace. Maverick pilots regularly receive approvals to operate in restricted or controlled airspace. Our procedures enable us to mitigate risks to flight operations in complex environments and airspace.

Related Services

Drone, RPAS and Unmanned Aerial Vehicles

Use drones to navigate into spaces that are inhospitable to manned entry.

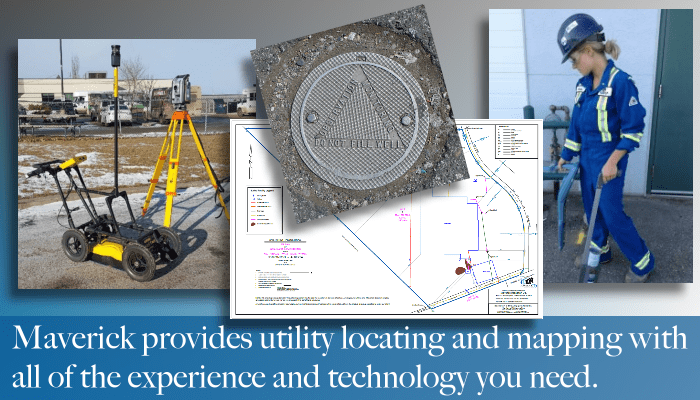

Utility Locating

Between Industrial, commercial and residential utility located Maverick Inspection Ltd. has the experience to get the job done right.

Remote Video Inspection

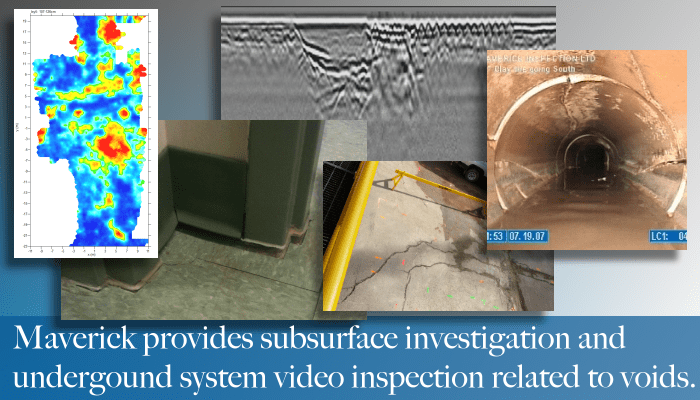

Use remote video inspection to enhance your sub surface inspection.