Video Inspection Equipment in all Shapes and Sizes

Remote Video Inspection (RVI) goes beyond the capabilities of traditional borescopes and pipe cameras, enabling inspection of inaccessible areas using advanced video systems. Also known as CCTV Inspection, RVI involves capturing imagery of internal structures, equipment, and components that may have physical constraints, safety risks, or other limitations. By utilizing video inspection cameras, you can easily locate and examine critical areas of interest without the need for extensive equipment disassembly or hazardous confined space entry. RVI offers a safe and efficient solution for comprehensive inspections, providing valuable insights into inaccessible spaces.

Robotic Crawlers

Tethered crawler systems up to 300m. EX systems available

Borescopes

6mm, 8mm, HD, sterio vision, 3D modeling & measurement

Push Cameras

Up to 120m in HD. EX systems available

Drones & Unmanned Aerial Vehicles

Internal or External systems are available

Underwater ROVs

4K video, 100m dive depth, 400m operating radius

Robotic Drop Camera Systems

Lightweight, portable camera systems for vertical asset inspections

Additional Services

Laser pipe profiling and FOSAR (Foreign Object Search And Retrieval) systems available

Remote Video Inspection

When it comes to camera inspection systems, there is a wide range of options available, from small video scopes to large robotic wheeled or tracked pipe crawlers. The choice of technology and method depends on the specific application, including industrial drone inspections.

In North America, sewer inspection is a prevalent camera inspection application due to the extensive aging drainage infrastructure in place.

However, for industries like Oil & Gas, Power Generation, Pipeline, and others, the equipment and experience requirements for camera inspections go well beyond the basics needed for sewer camera work. At Maverick Inspection, we specialize in providing advanced camera inspection services tailored to these industries, utilizing cutting-edge technology and the expertise of our experienced technicians.

Maverick Inspection Ltd., based in Edmonton, Alberta, is a trusted leader in delivering effective solutions and pioneering new applications and technologies for remote camera inspection in various industries across Canada. Our expertise includes pipe inspection, pressure vessel inspection, and providing valuable turnaround support.

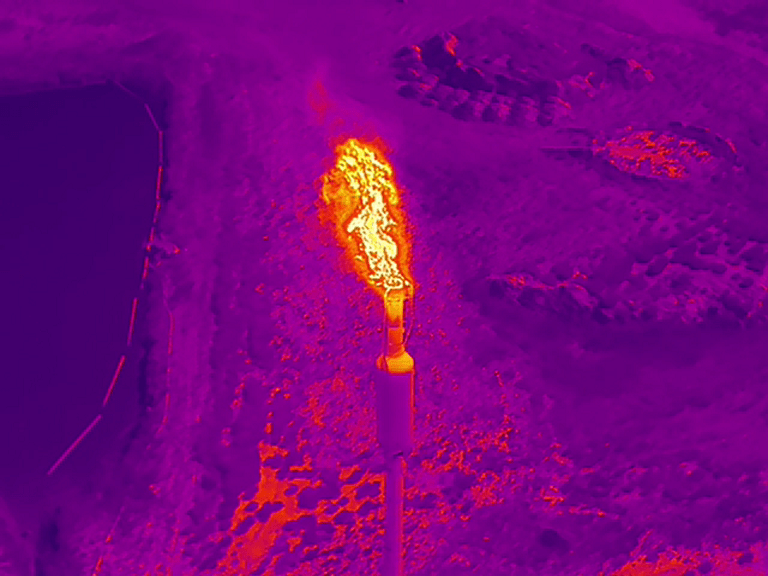

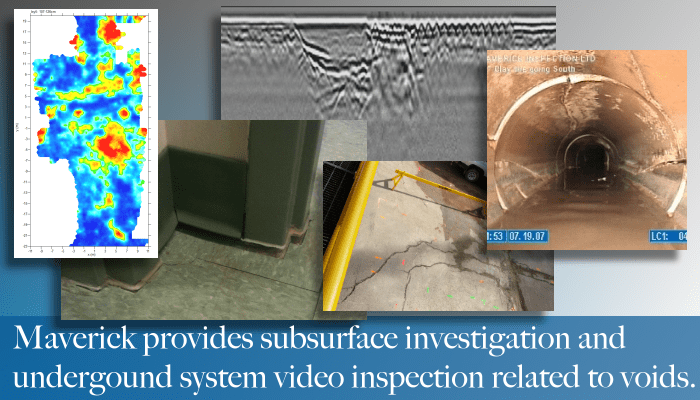

In addition to remote video camera systems, we integrate other cutting-edge technologies to enhance our inspection capabilities. These include ground penetrating radar, infrared thermography, utility locating, laser pipe profiling, and retrieval systems. Furthermore, we employ advanced measurement software to conduct in-depth analysis of the video inspection results, ensuring comprehensive and accurate assessments.

Our RVI Department

As the premier video inspection service provider in Canada, Maverick Inspection boasts an extensive array of camera inspection systems. We understand that a diverse range of equipment is required to effectively inspect various components such as pressure vessels, pipelines, piping, rotating equipment, and heat exchangers. Below are just a few examples of the essential video camera options we offer to tackle challenging and hard-to-access scenarios.

Call For an Estimate:

(780) 467-1606

Technology and Applications

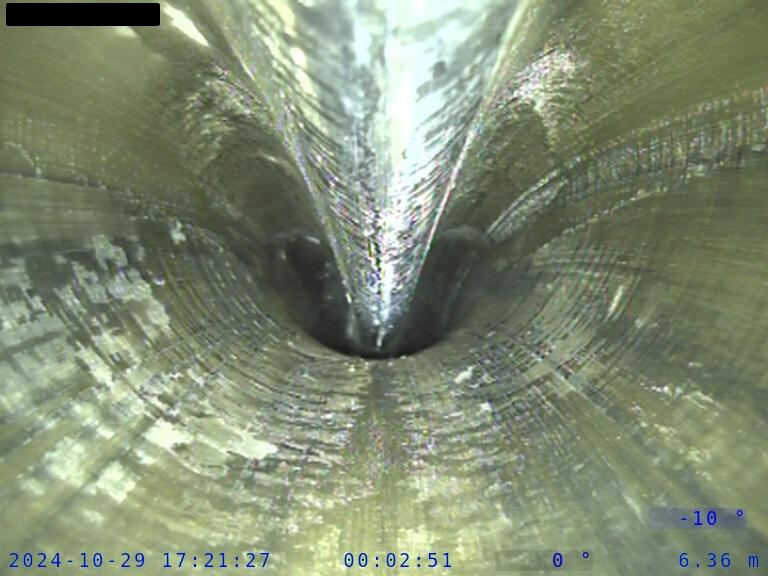

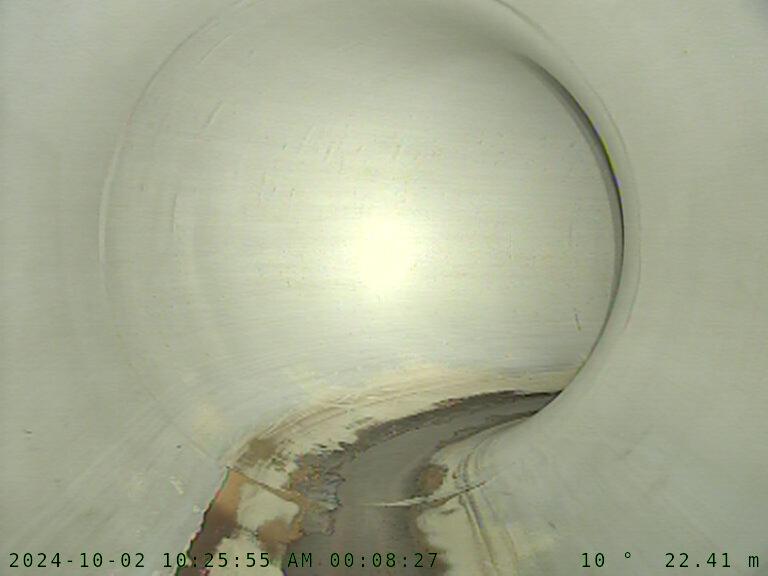

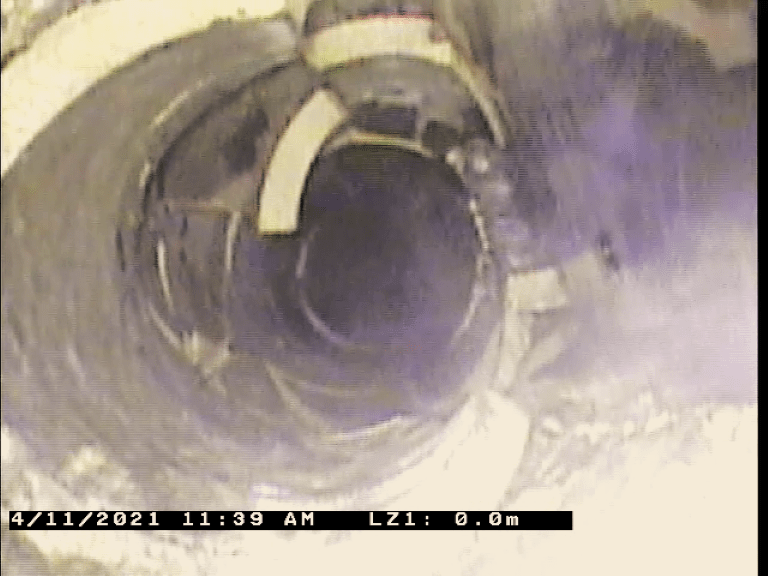

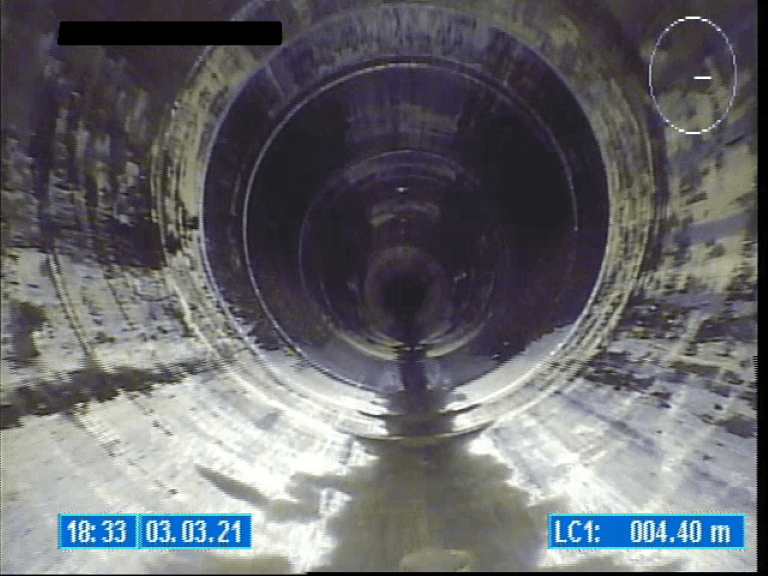

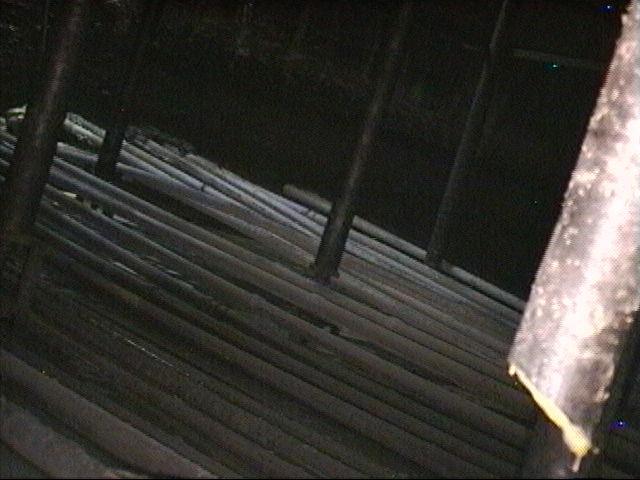

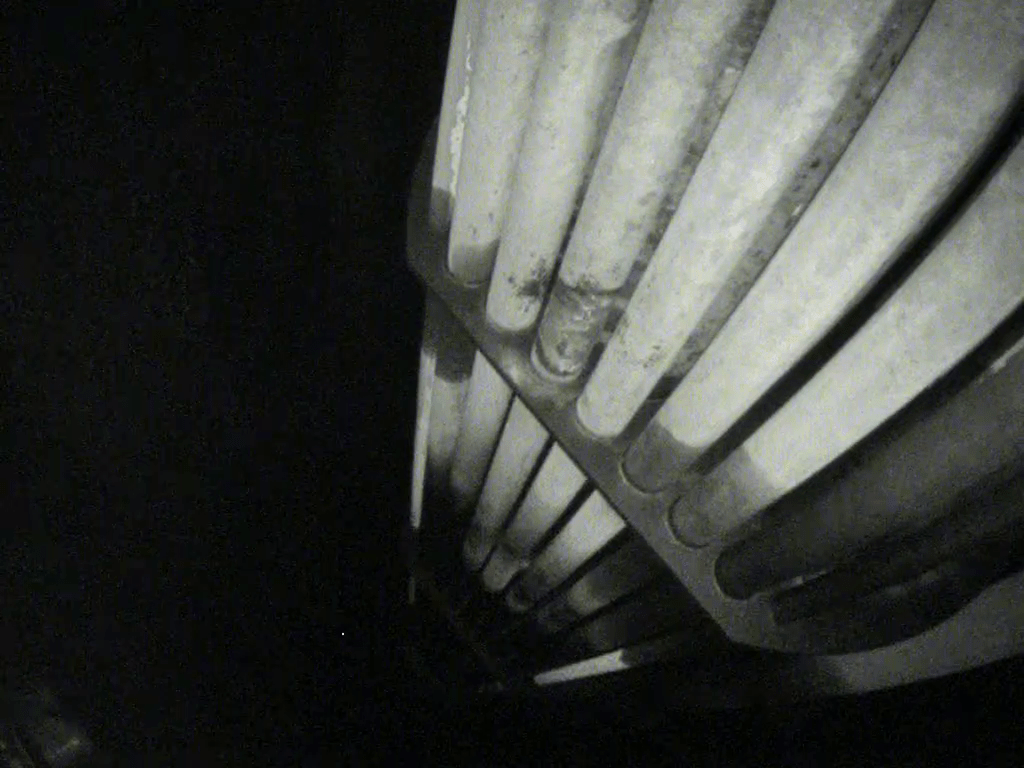

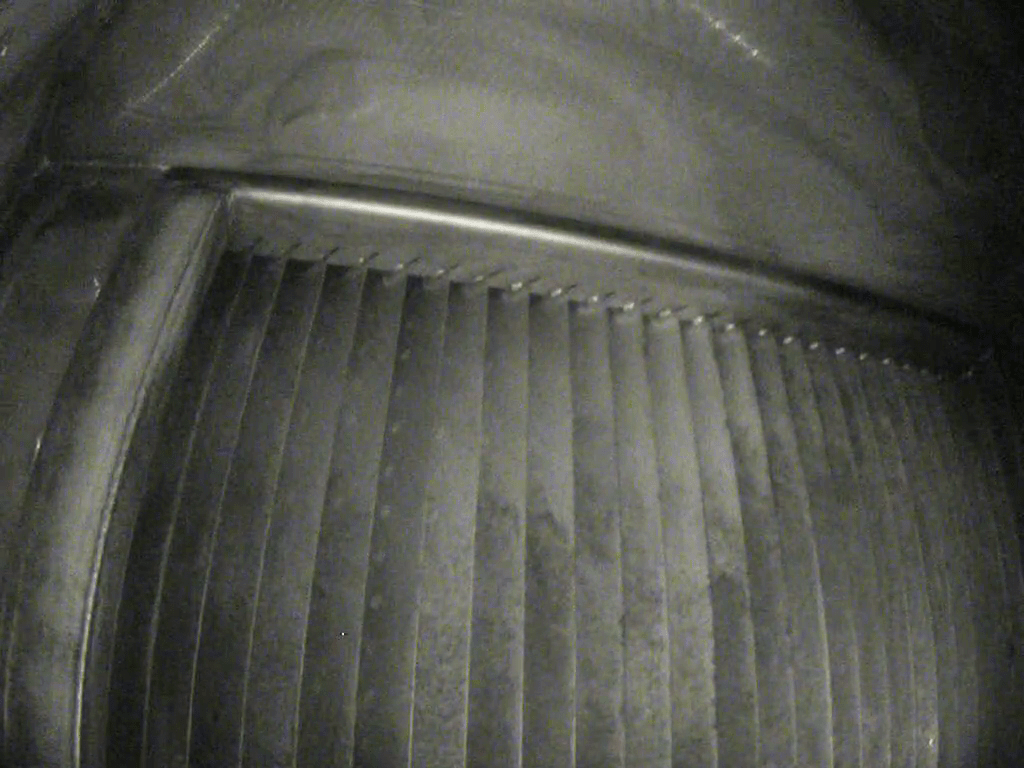

ROBOTIC CRAWLER SYSTEMS

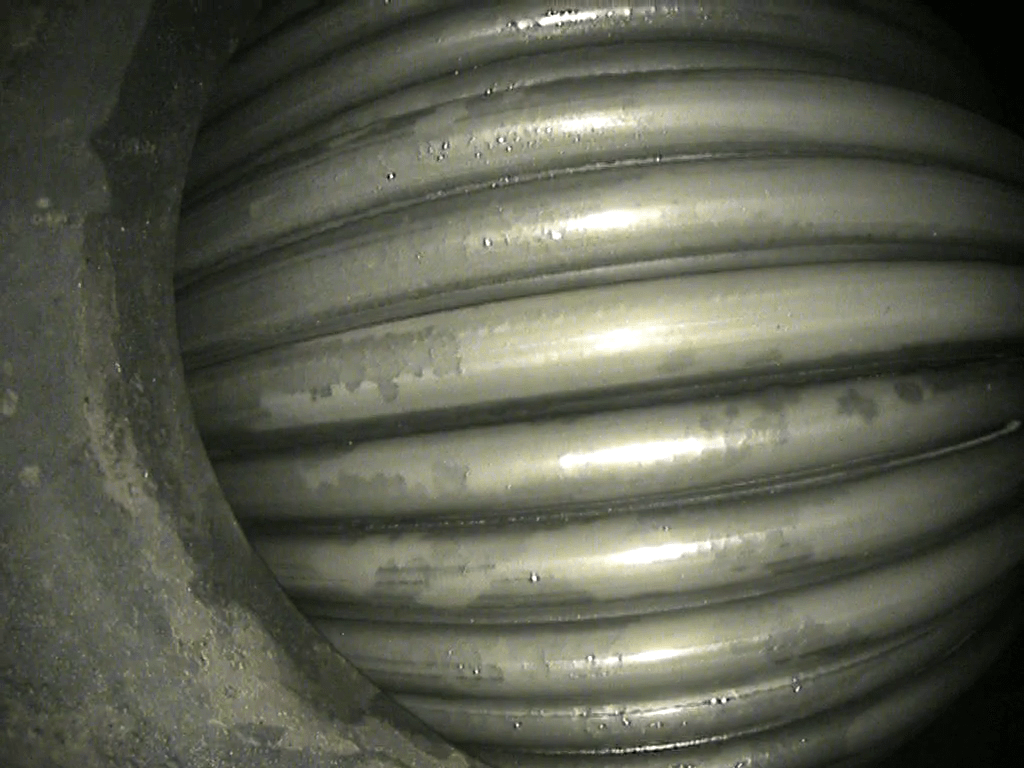

Maverick Inspection offers a diverse range of robotic crawler systems tailored for various projects and environments. These systems are self-propelled and provide full remote control over essential features such as panning, tilting, lens focusing, optical zoom, and light intensity adjustment. These units excel in complex remote navigation scenarios like large-radius piping bends and pipelines. The systems can access openings ranging from 4″ to 72″ and offer long-range capabilities up to 300m. Our systems are suitable for use in explosive, hazardous atmospheres and underwater environments, meeting CSA Class I Division I and intrinsically safe specifications.

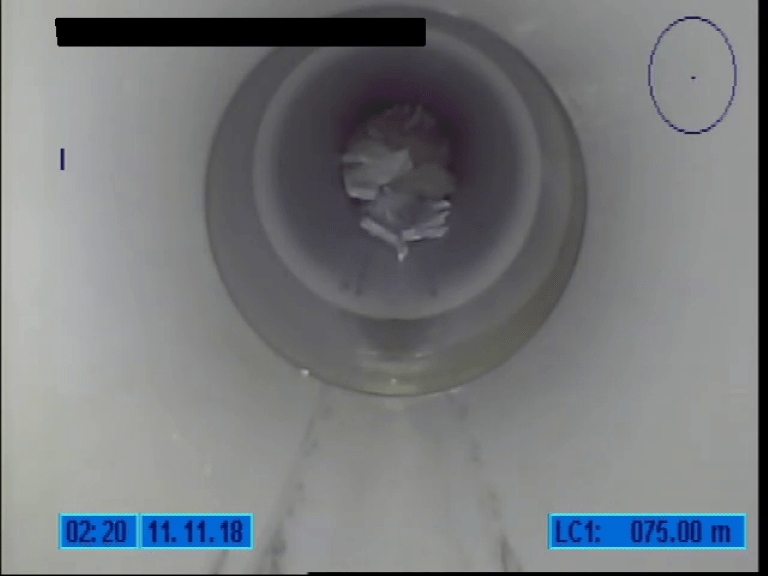

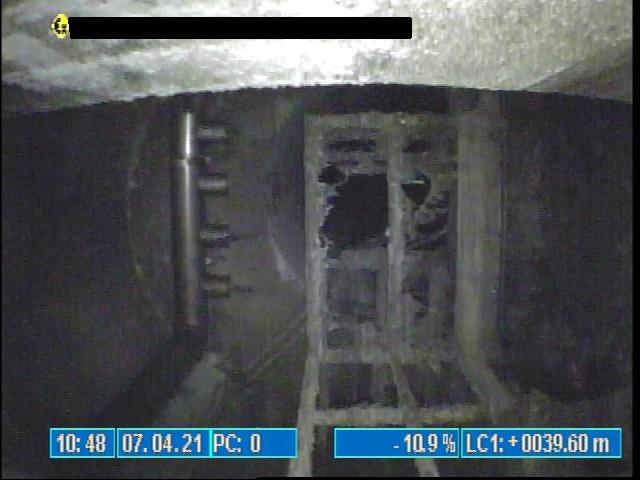

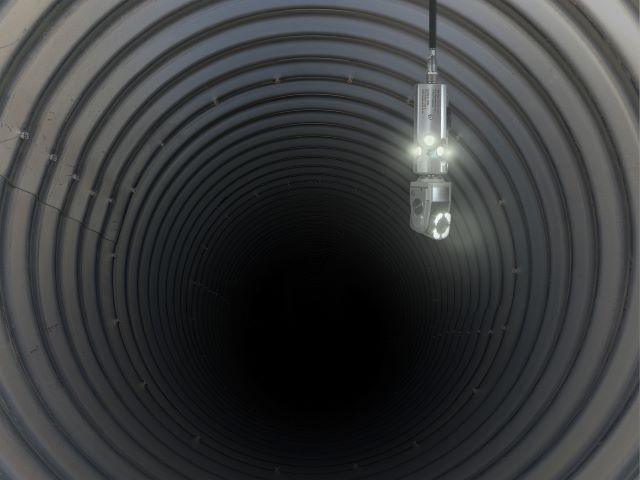

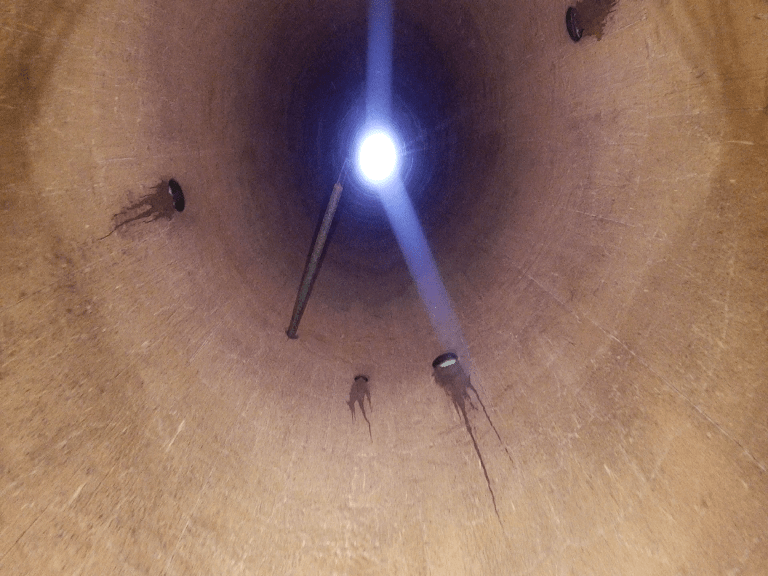

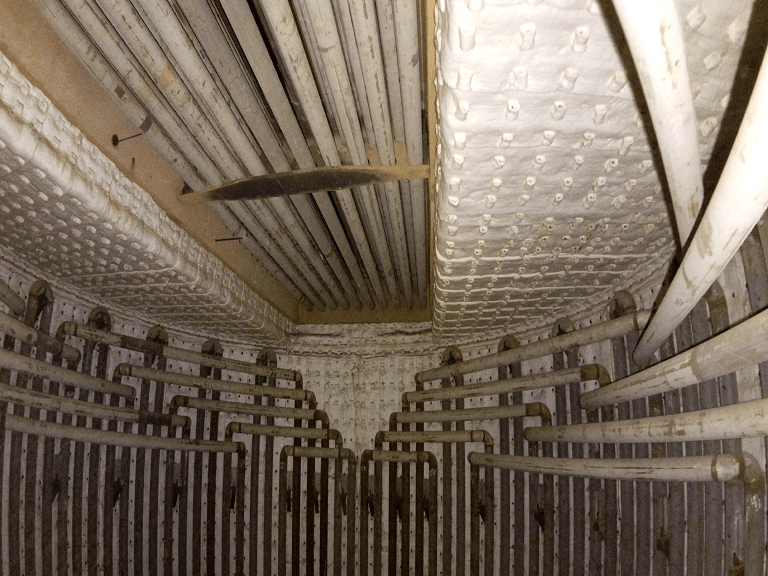

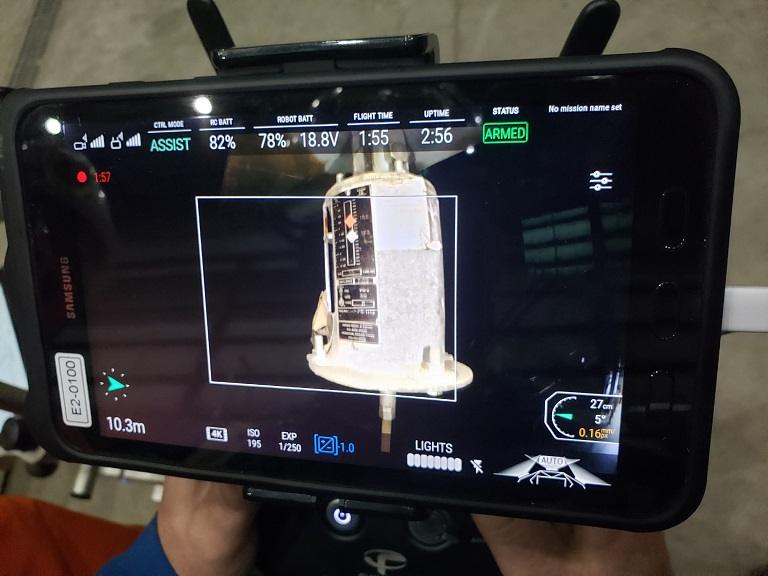

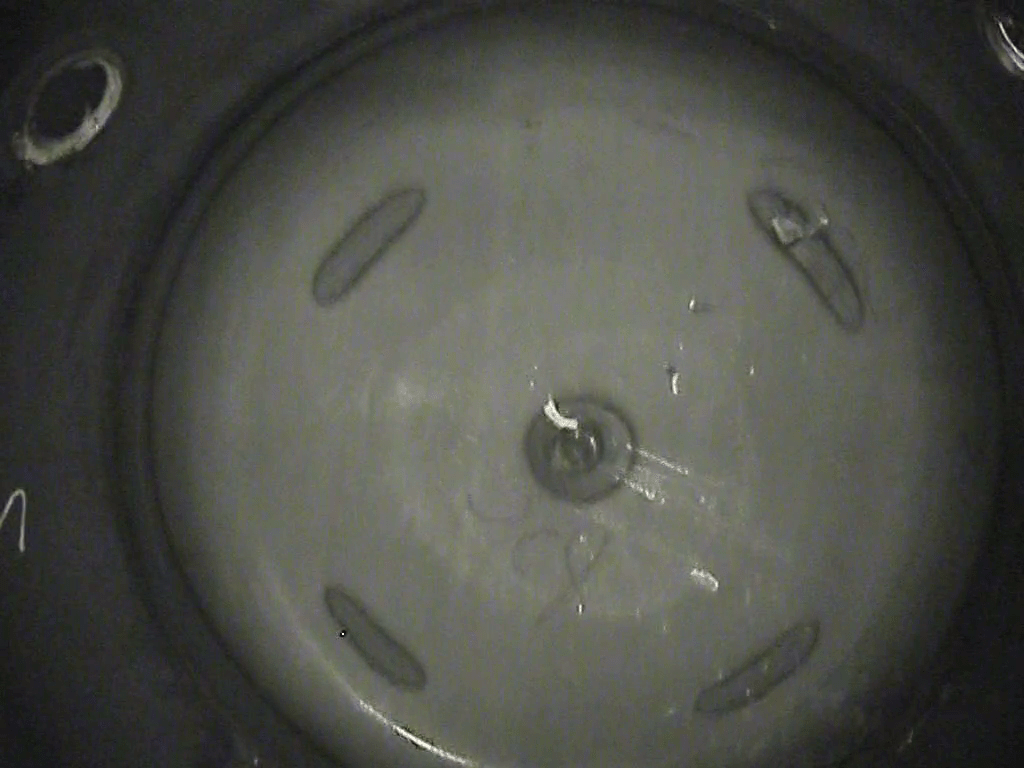

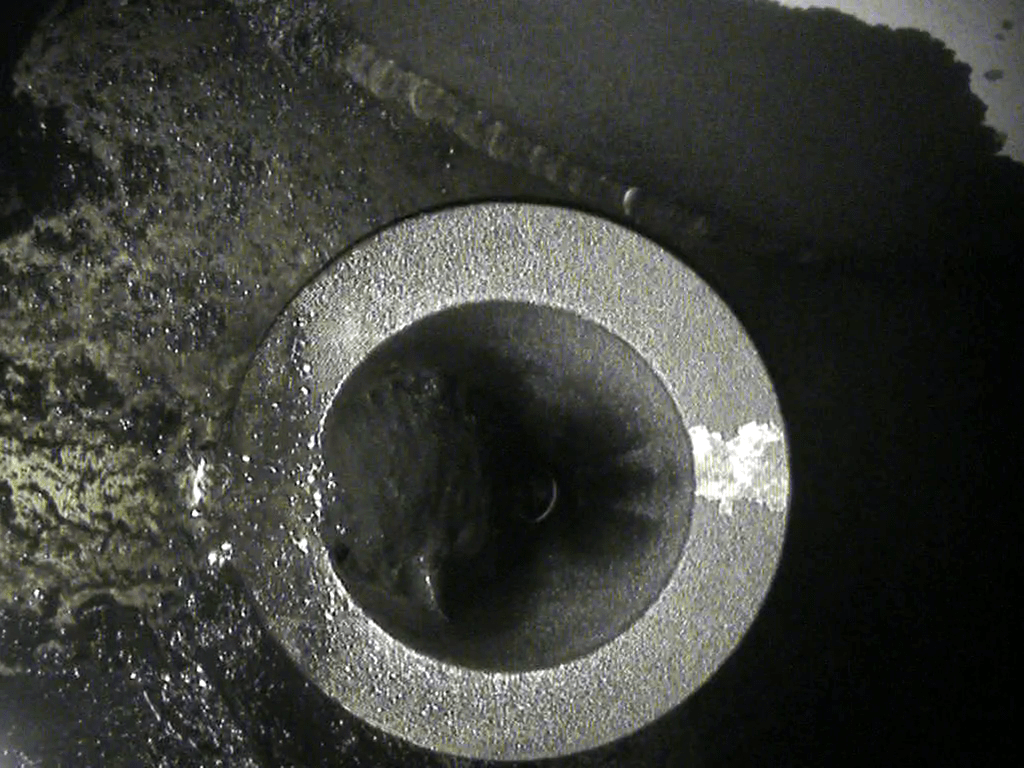

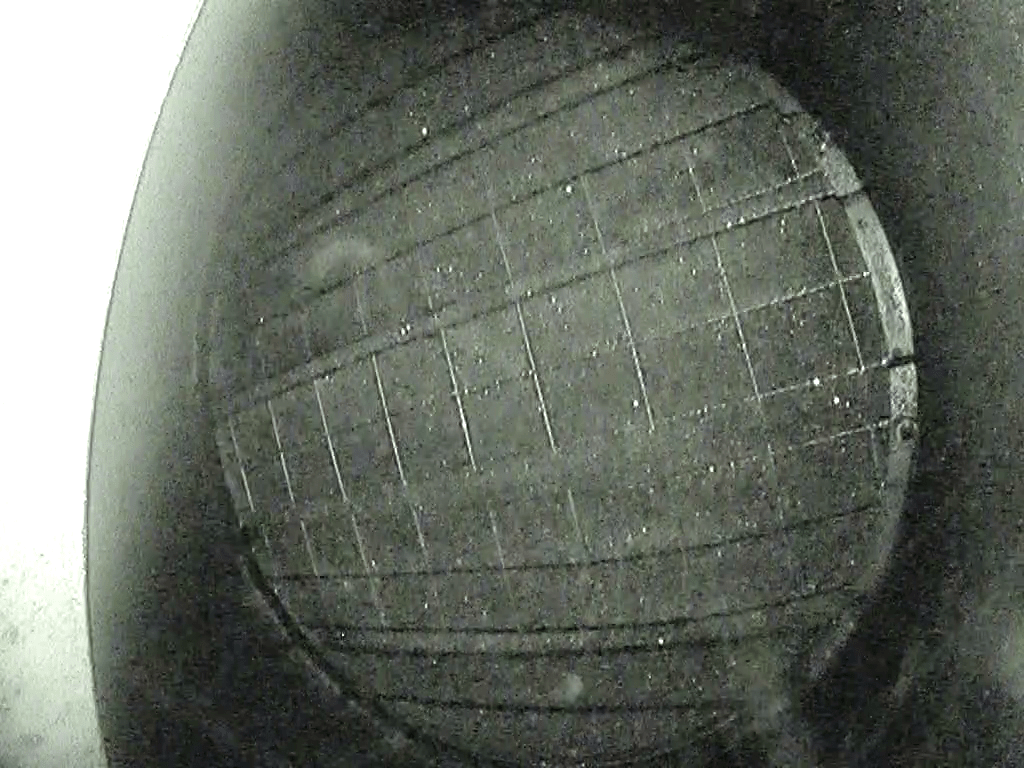

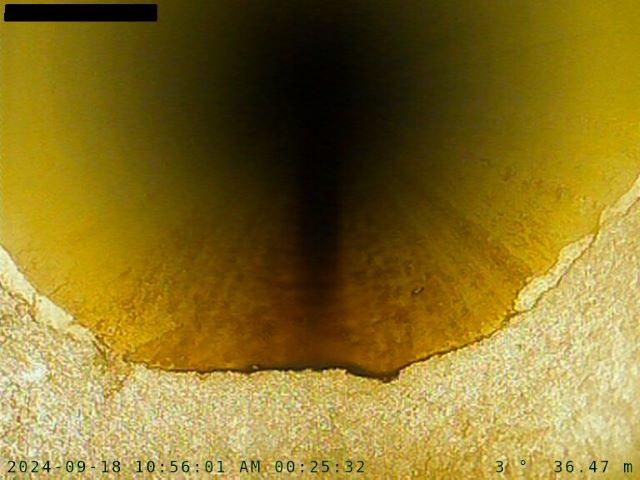

ROBOTIC DROP CAMERA SYSTEMS

A robotic drop camera system is a lightweight, tethered camera that can be vertically lowered down inside assets such as manholes, tanks, vessels, furnace or chimney stacks, etc. This system provides the same remote control of features as our robotic crawler systems, allowing complete 360 degree inspections. With an access requirement of only 5″, these cameras allow the inspection of equipment without the need for extensive disassembly. Just remove a flange and we’re good to go. These systems are also CSA Class I Division I rated, ensuring we are safe and compliant within even the most hazardous of environments.

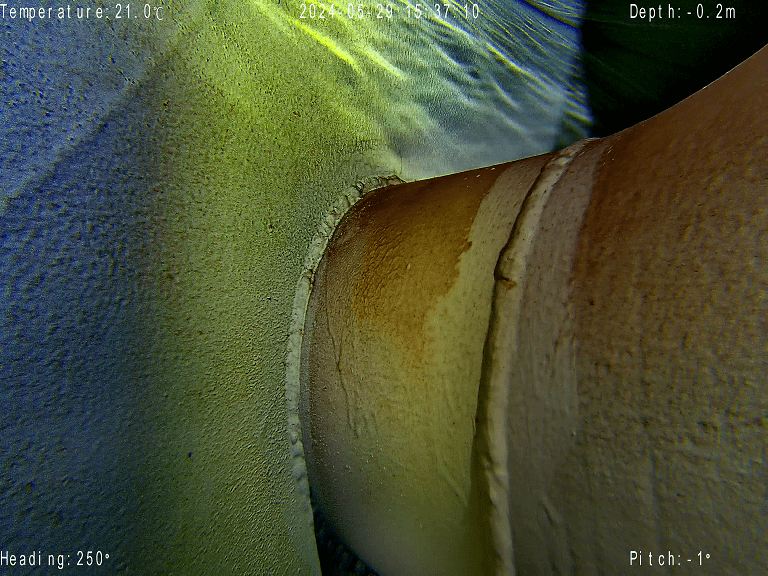

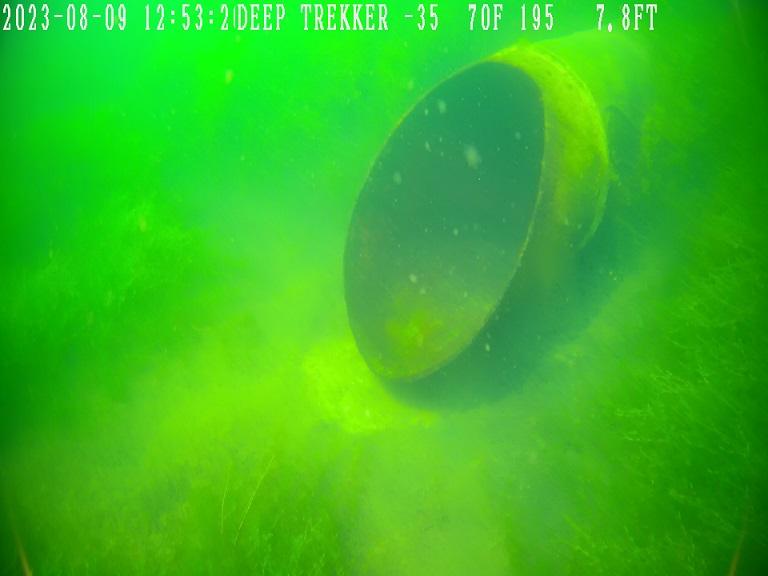

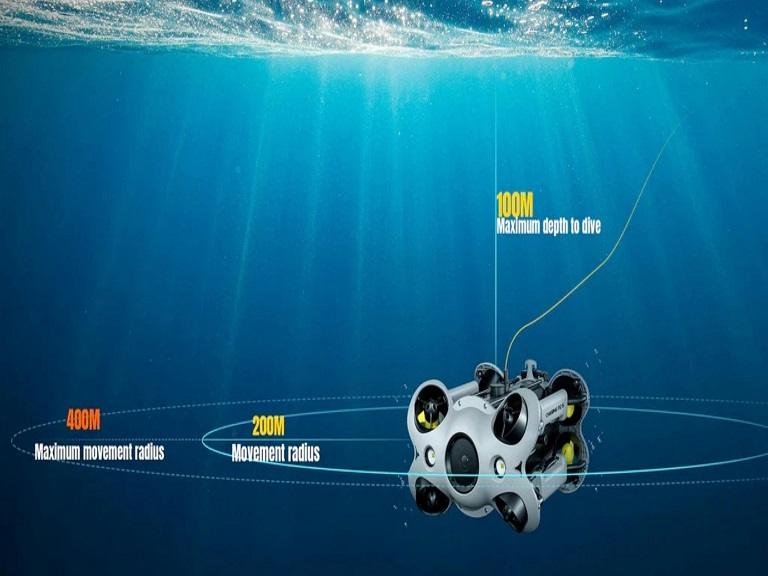

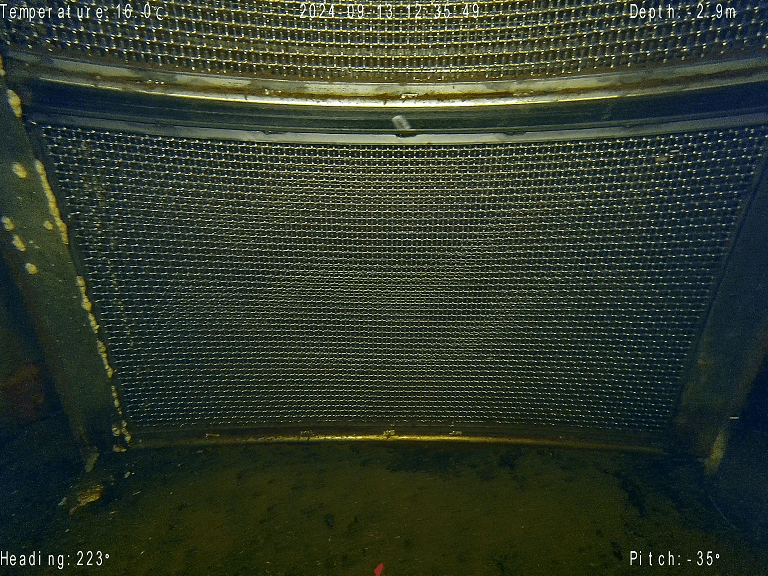

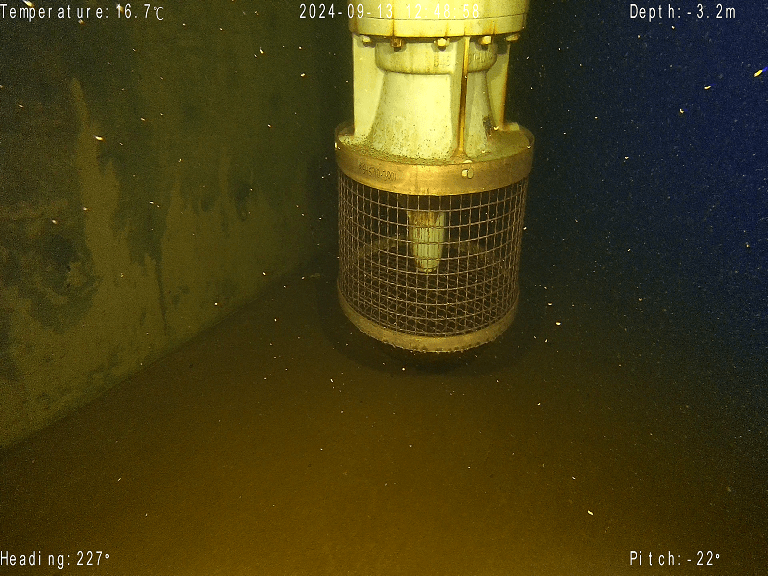

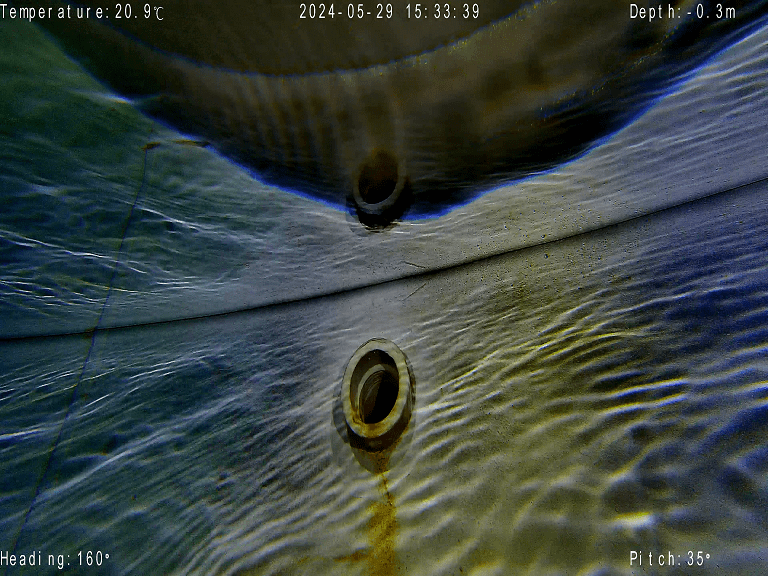

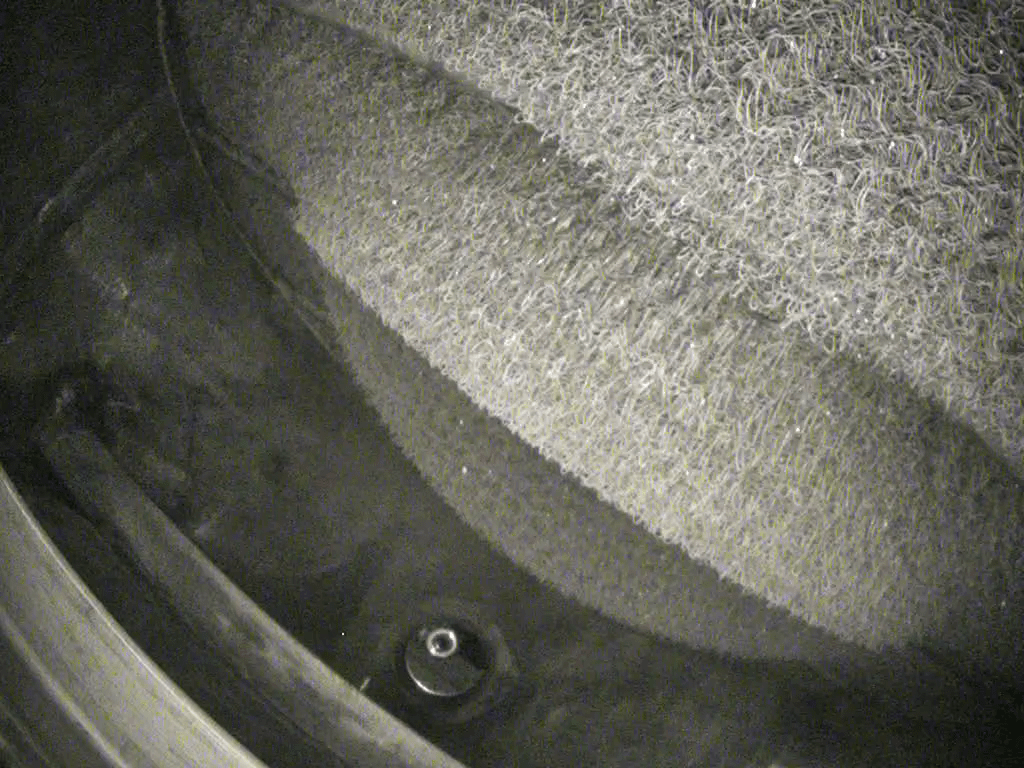

UNDERWATER ROVS

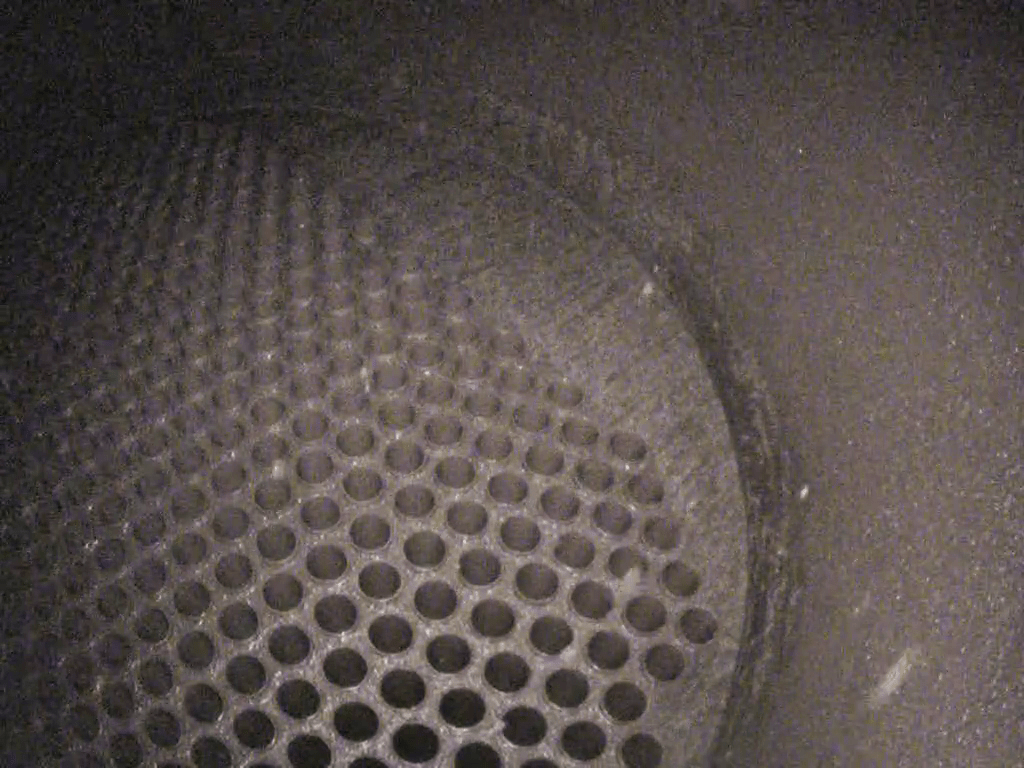

Maverick Inspection offers underwater ROV systems for inspecting underwater assets such as water storage tanks, pond inlets and outlets, or pump suction screens. These systems allow for the inspection of assets without the need for draining and manned entry, saving time and providing additional safety to personnel. These systems are capable of 100m dive depths with an operating radius of 400m. They are battery operated with operating times of up to 4 hours, with additional backup batteries available for the longer missions. Our units are equipped with 4K quality cameras and 8 vectored thrusters for omnidirectional movement, ensuring our technicians are able to gather the data our clients require. These units can also be equipped with accessories such as additional floodlighting for the darkest environments, or a grabber claw for underwater retrieval efforts.

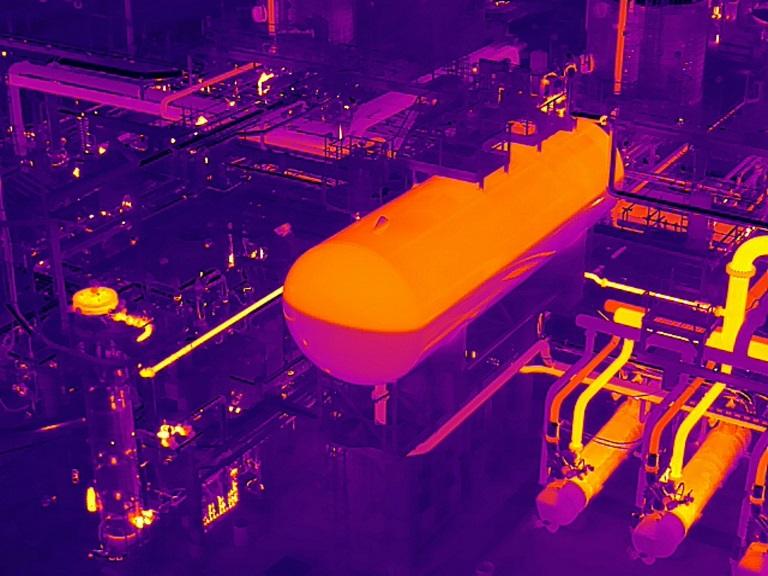

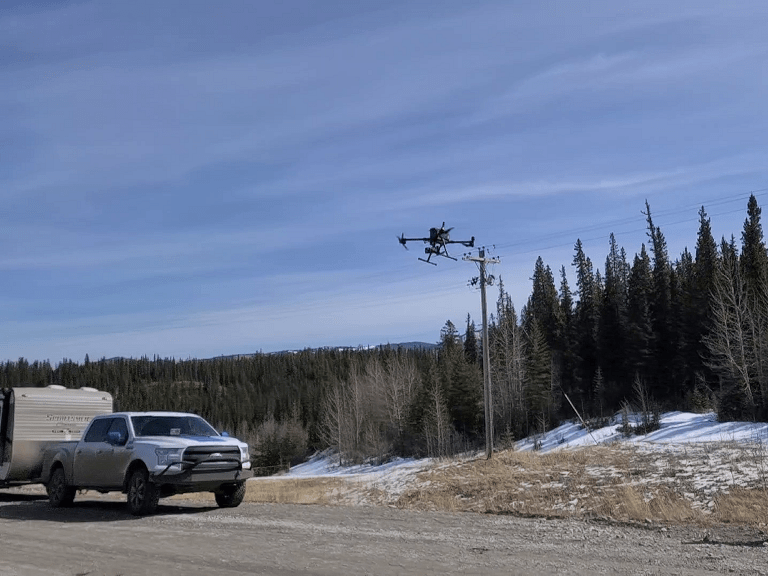

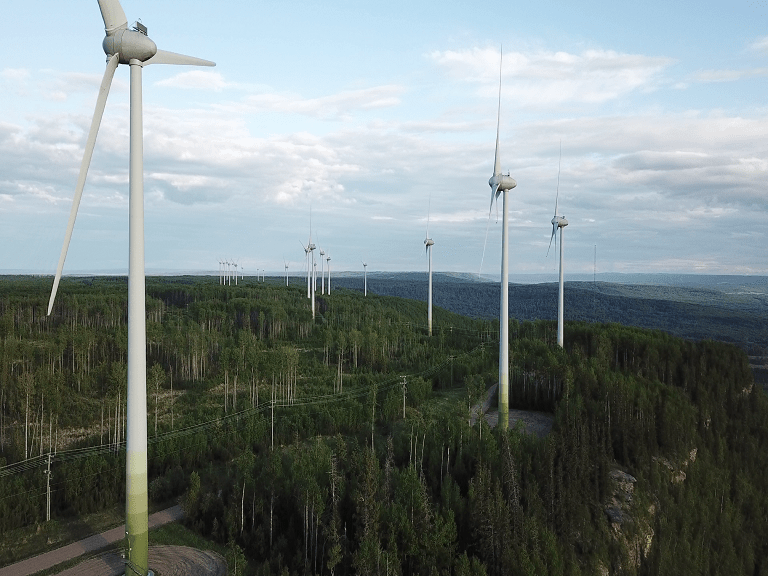

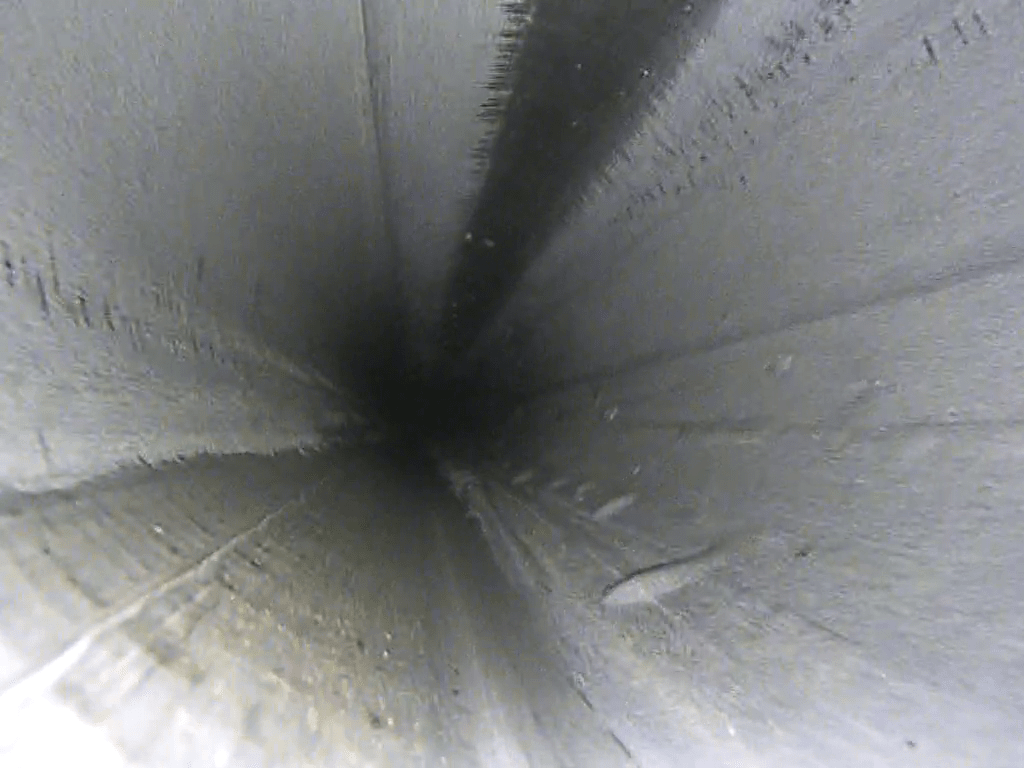

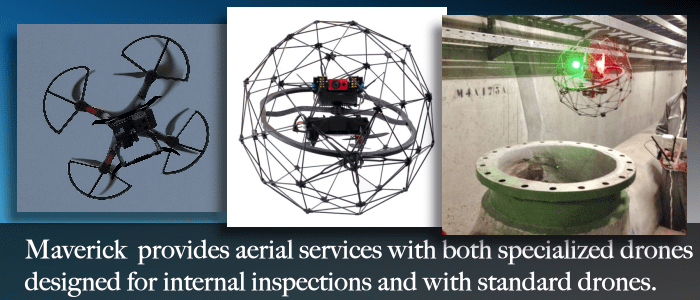

INDUSTRIAL DRONE INSPECTION SYSTEMS

Maverick brings decades of experience and expertise to industrial drone services. We understand the unique requirements of this specialized field, which demands specially designed equipment, rigorous training, and precise procedures.

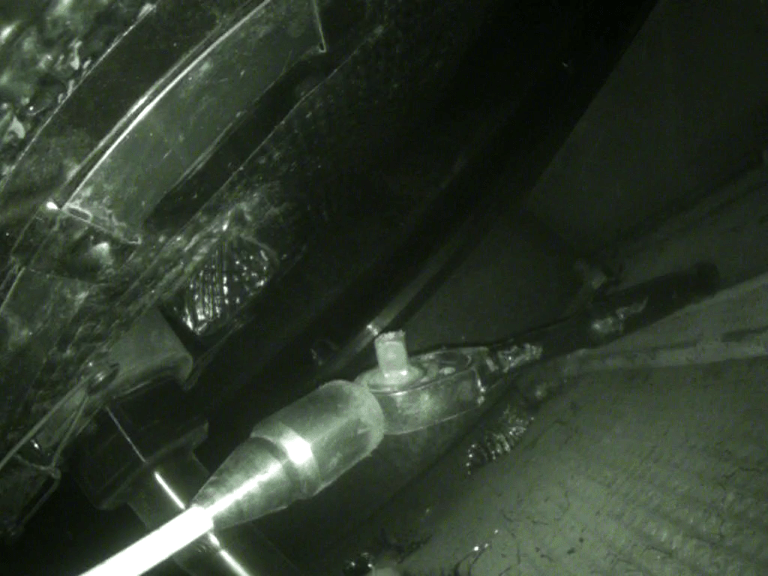

For internal inspections, we rely on Flyability’s ELIOS 2 system. This cutting-edge system is purpose-built for safe and efficient video inspections of plant equipment internals. With its collision tolerance and advanced capabilities, ELIOS 2 is specifically engineered for inspections of stacks, chimneys, vessels, piping, and other industrial structures.

In addition to internal inspections, Maverick offers traditional aerial drone inspections for a range of applications. From roof scans and building envelopes to aerial mapping, our drone services go beyond the ordinary. Coupled with our expertise in CAD, GIS, geomatics, and mapping technologies, drone systems become powerful tools that deliver exceptional results.

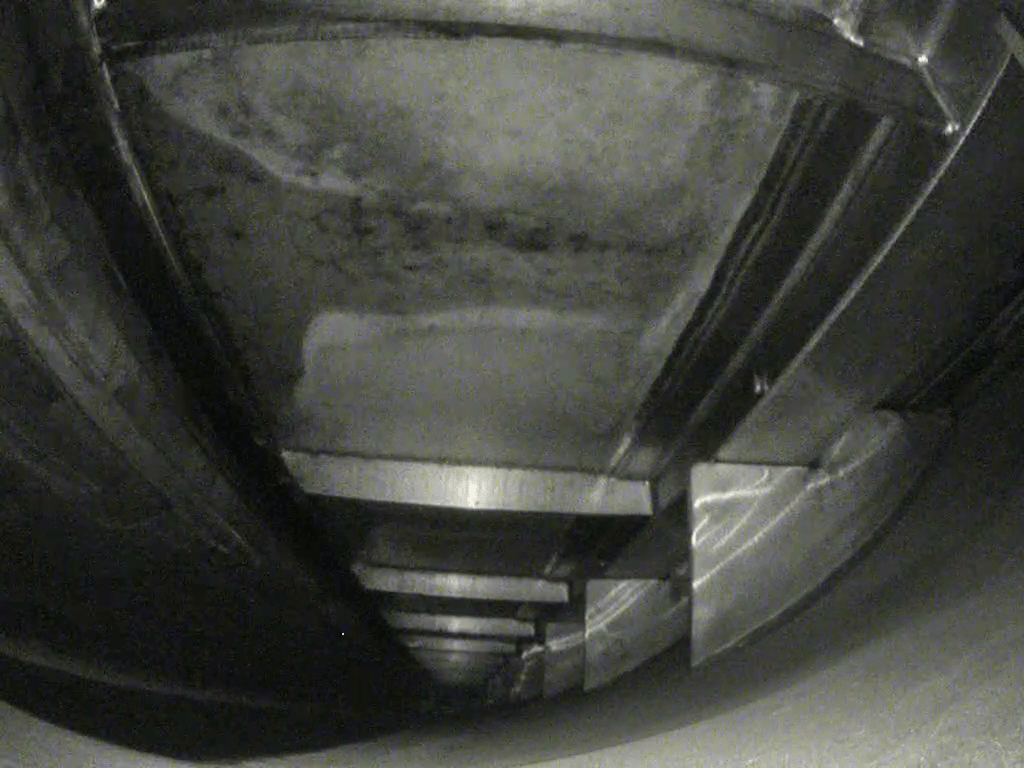

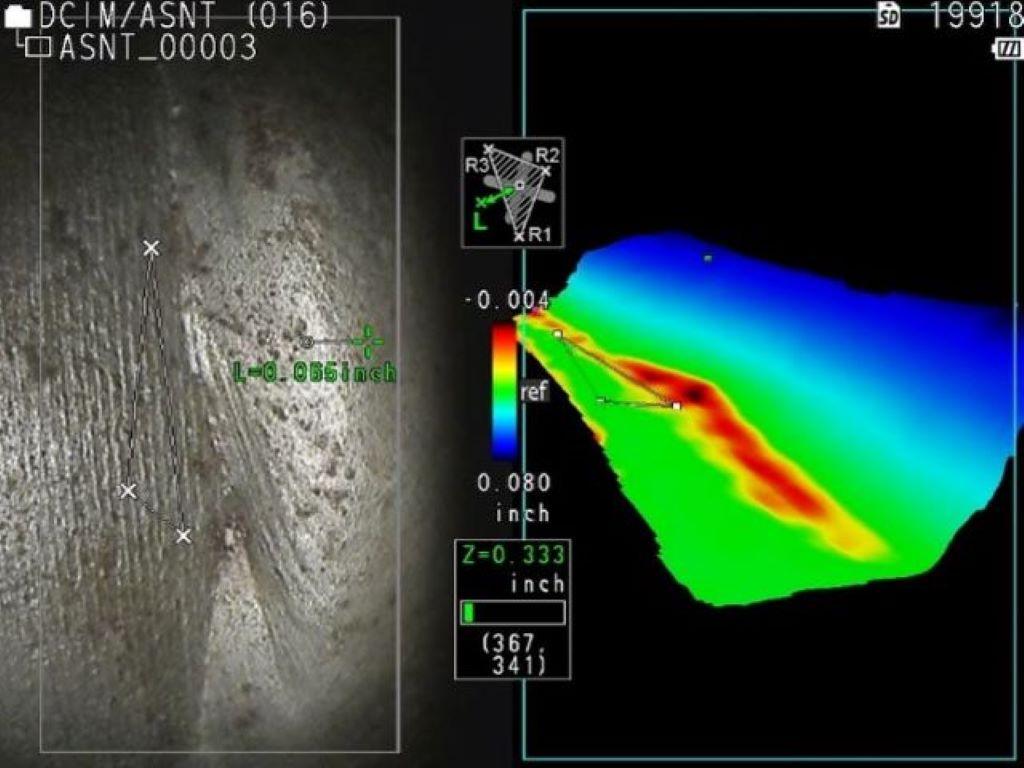

BORESCOPES

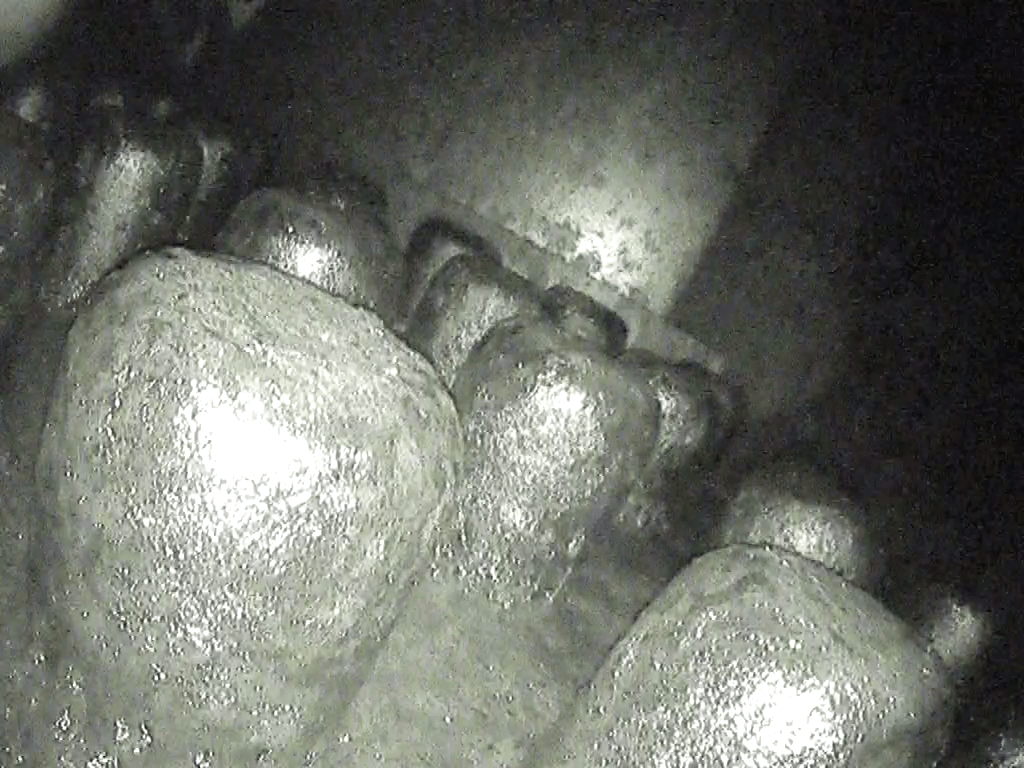

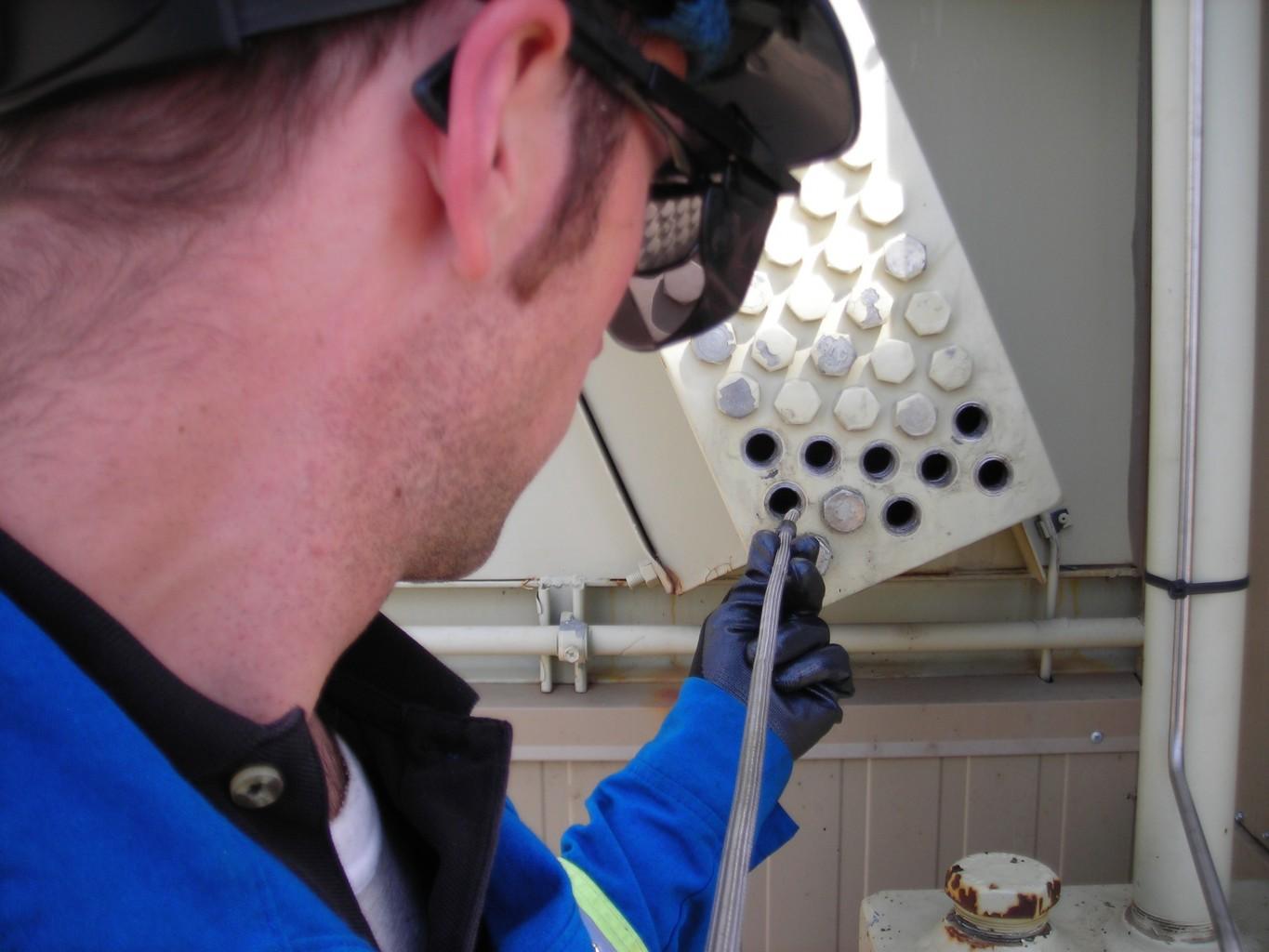

A video scope, fiberscope, or borescope is a versatile tool used for high-resolution inspection of tubes, pressure vessels, mechanical components, and equipment with limited accessibility. Maverick utilizes these advanced video inspection systems, which feature flexible and portable designs, high-intensity LED lighting, and articulating heads with various lenses. With diameters as small as 6 mm, they are ideal for inspecting rotating equipment, engine components, small vessels, and equipment with small inspection ports. Our video inspection systems are often complemented with measurement software for enhanced analysis and reporting capabilities.

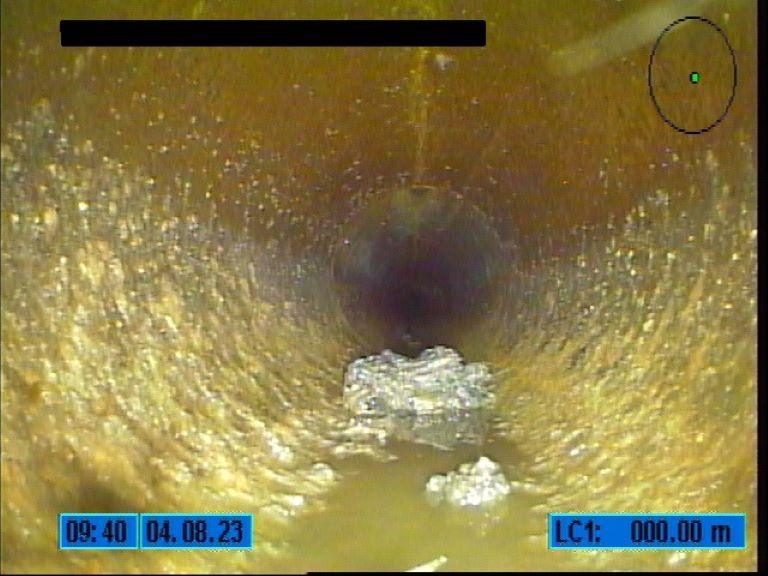

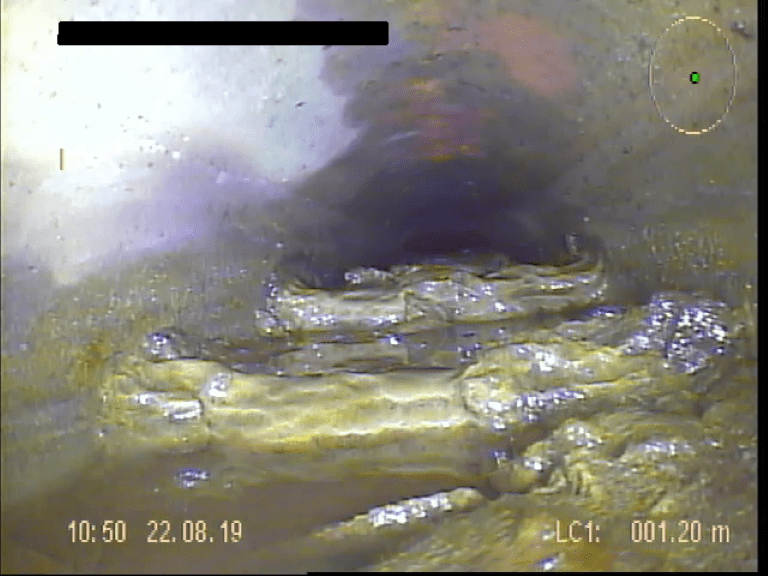

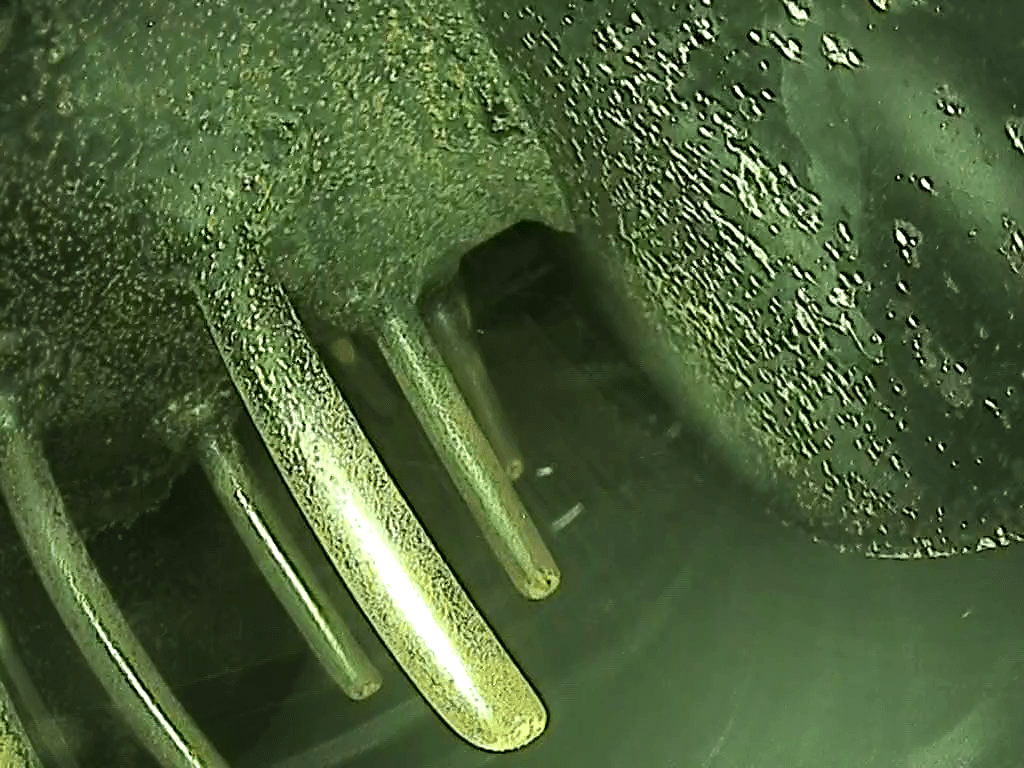

PUSH CAMERA SYSTEMS

Maverick Inspection offers advanced push camera systems, also known as sewer cameras or borescopes. These systems are specifically designed for small diameter piping, pressure vessels, and other applications that require a rugged, push-style camera head. With various sizes and features available, our systems are versatile and cater to different inspection needs. They are commonly used for process piping and pipeline inspections. These systems provide full remote control over essential features (where applicable) including panning, tilting, lens focusing, optical zoom, and light adjustments. Additionally, our push camera systems offer interchangeable camera heads for different applications, making them adaptable to various environments. They are highly suitable for underwater applications, with some systems capable of operating at depths of up to 1000 feet. We also provide CSA Class I Division I explosion-proof systems for hazardous environments, ensuring safety and compliance.

ADDITIONAL SERVICES

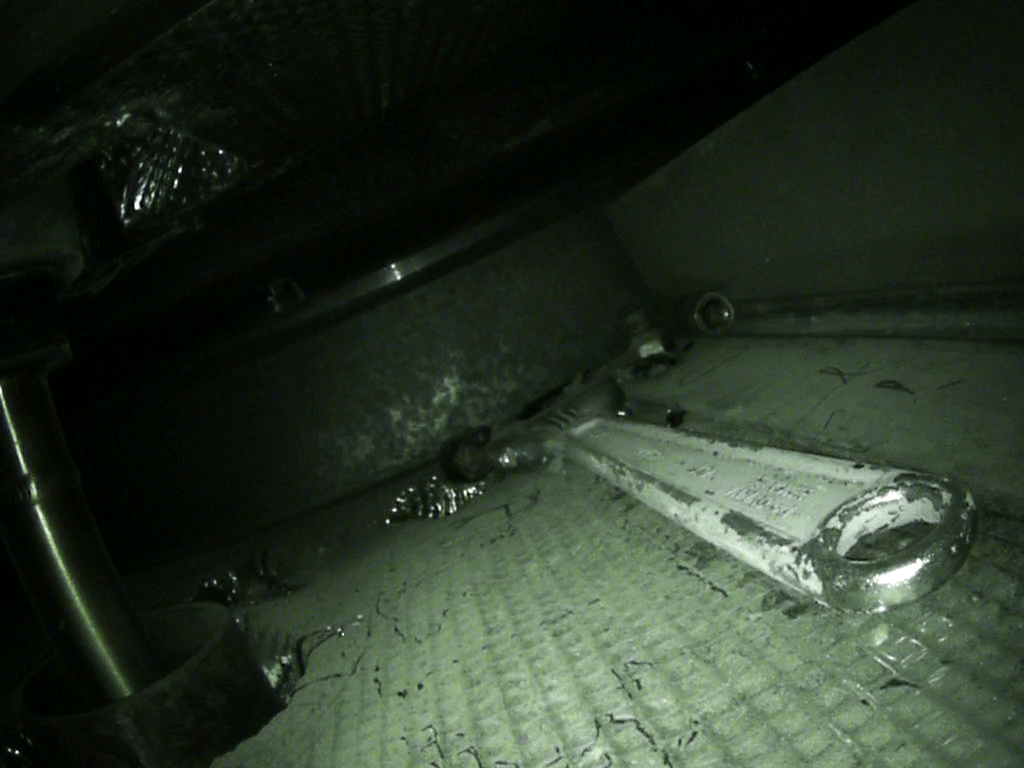

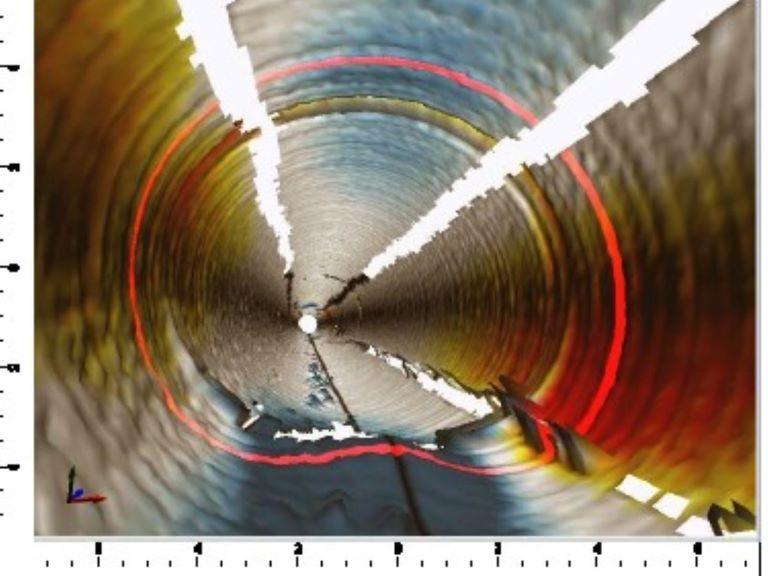

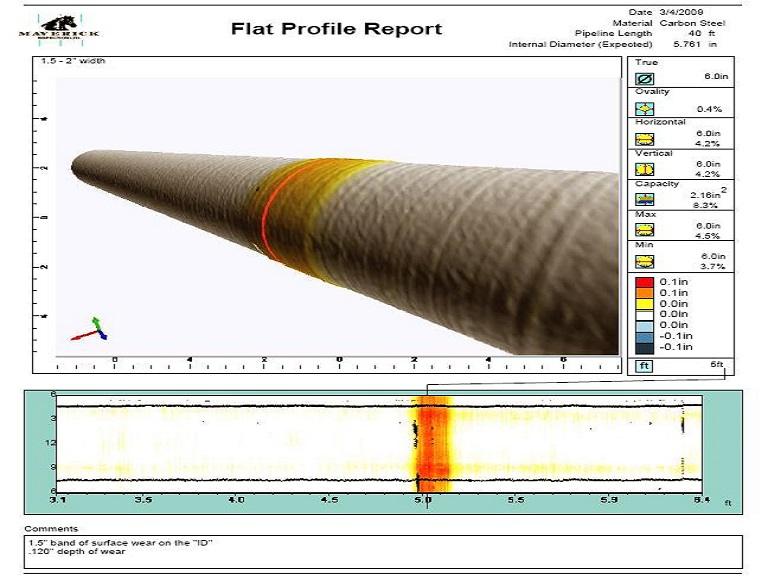

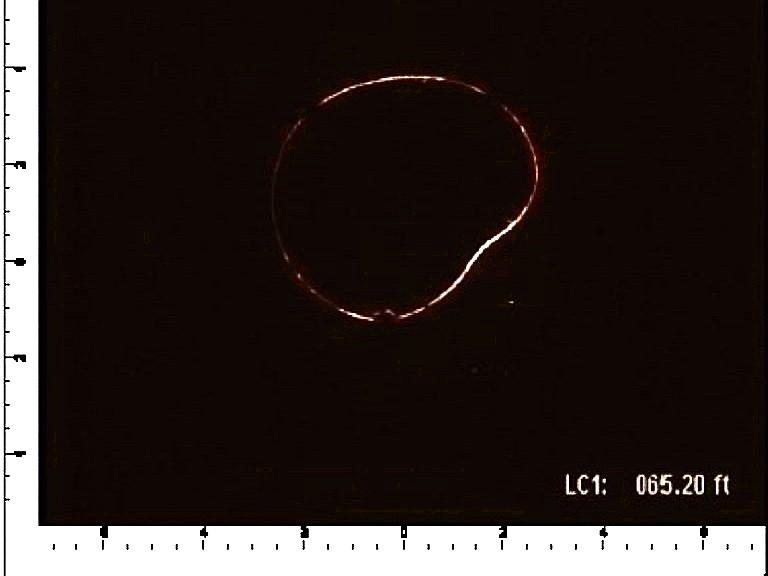

Maverick offers additional services that may be paired with our traditional RVI services. We provide laser pipe profiling for measuring ovality of piping. A laser attachment is affixed to one of our robotic crawler systems to gather laser visual data. Advanced software is then used to analyze the laser data and generate reports based on our clients’ needs. Reports that can be generated include flat graphs, true diameter, ovality, minimum or maximum diameter, XY diameter, or capacity.

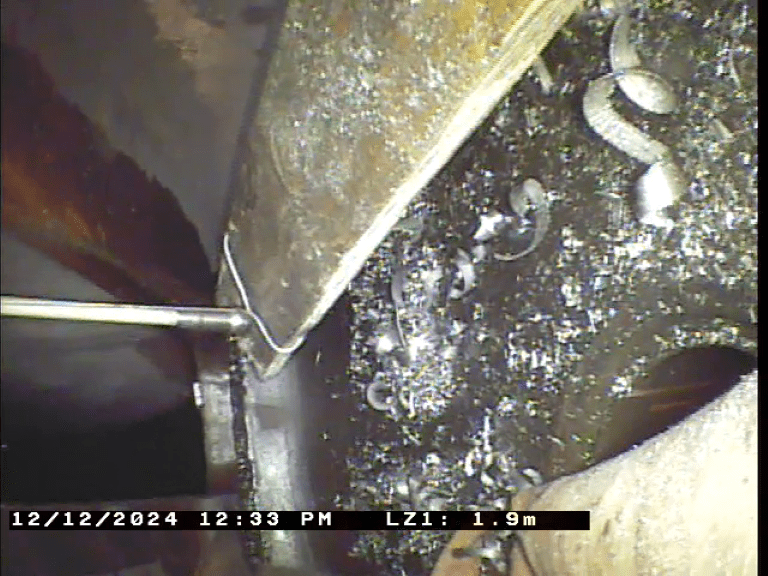

Maverick also offers complete FOSAR (Foreign Object Search And Retrieval) kits that can be used in conjunction with any of our robotic crawler, push camera, or borescope systems. With attachments ranging from grabber claws, snares, and magnets, Maverick technicians are equipped to tackle even the most complex of retrieval scenarios.

F.A.Q.

Every job has it’s own unique aspects. Fill us in on the details.

What is the difference between push cameras and crawlers?

Push cameras are designed to navigate through small-diameter piping using a rigid cable and a camera head. Crawlers, on the other hand, are robotic systems that use tracks or wheels to traverse larger piping and perform inspections.

What types of piping can be inspected using remote video inspection?

Remote video inspection can be conducted on a wide range of piping, including sewer lines, drainage systems, industrial pipelines, and pressure vessels. The size and configuration of the piping system will determine the most suitable inspection method and equipment.

How does remote video inspection help identify issues?

By deploying a push camera or crawler system, remote video inspection allows for real-time visual assessment of equipment conditions. This helps identify issues such as cracks, leaks, blockages, corrosion, and other forms of damage or deterioration.

Can remote video inspection capture high-quality footage?

Yes. Modern push cameras and crawlers are equipped with advanced camera technology that can capture high-resolution video footage and images. This enables inspectors to closely examine pipe interiors and detect even minor defects.

Is remote video inspection suitable for confined spaces?

Remote video inspection is particularly beneficial for inspecting confined spaces such as tanks, vessels, and other enclosed structures. By using push cameras and crawlers, inspectors can access and assess these spaces without the need for physical entry, reducing risks to personnel and ensuring thorough inspections.

Related Services

Drone, RPAS and Unmanned Aerial Vehicles

Use drones to navigate into spaces that are inhospitable to manned entry.

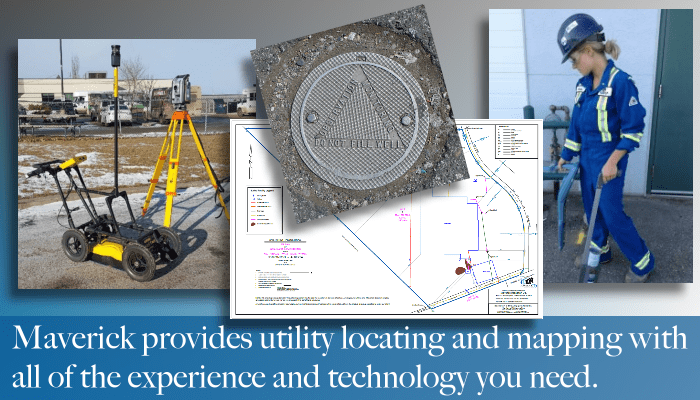

Utility Locating

Between Industrial, commercial and residential utility located Maverick Inspection Ltd. has the experience to get the job done right.

Remote Video Inspection

Use remote video inspection to enhance your sub surface inspection.